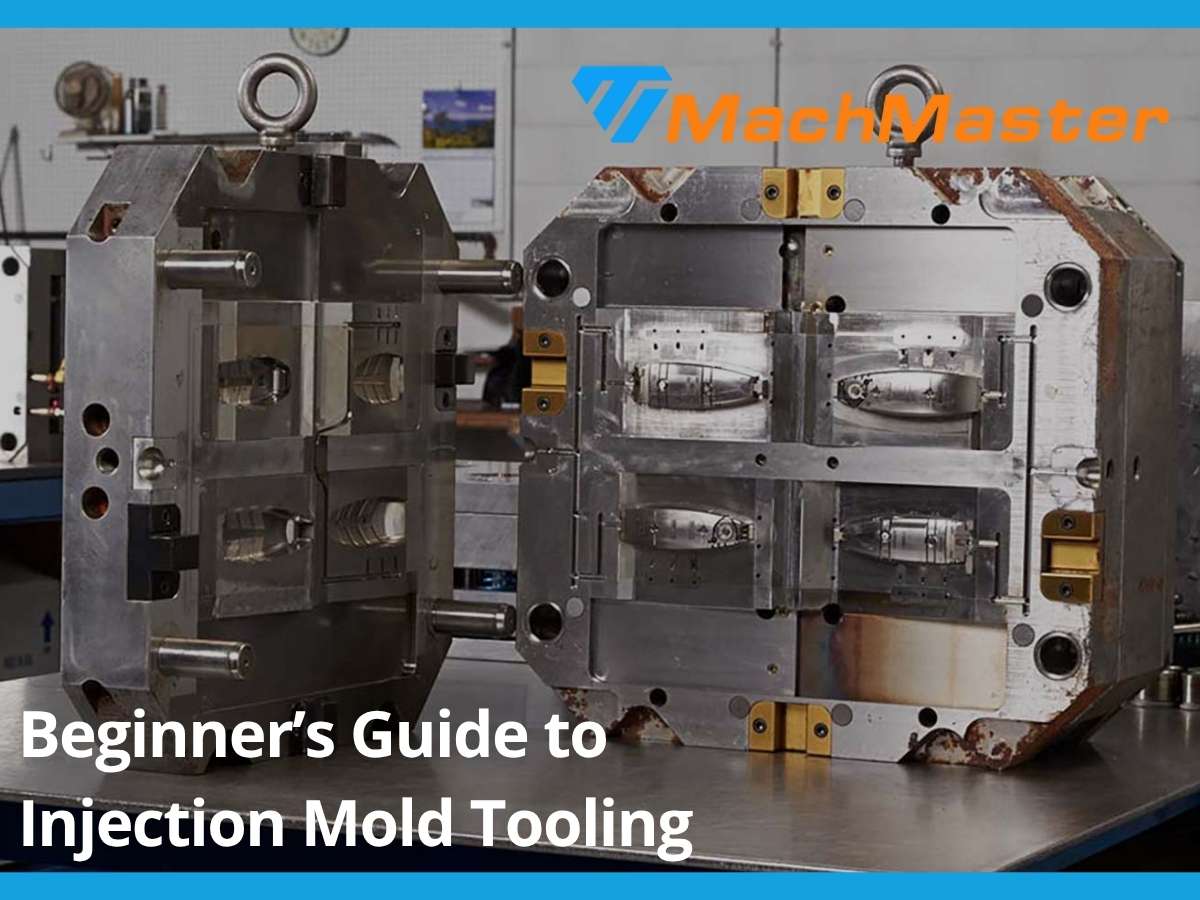

Beginner’s Guide to Injection Mold Tooling

I still remember the plastic sample part sitting on my desk. It looked great. Clean lines. Perfect fit. But the mold? That was another story.

Explore Our Perspectives on Precision, Innovation, and Manufacturing.

I still remember the plastic sample part sitting on my desk. It looked great. Clean lines. Perfect fit. But the mold? That was another story.

Years ago, I lost a project and I didn’t understand why. I’d sent drawings, material specs, and deadlines. Everything was covered. Or so I thought.

I once lost a whole week chasing a problem I didn’t understand. Parts were failing QA, but nobody could figure out why. It wasn’t shrinkage.

I once promised a client a delivery date I couldn’t keep. Why? Because I didn’t fully understand how long injection molding really takes. And I

Sometimes the problem isn’t the part. It’s the process. Years ago, I kept getting complaints from customers about loose connections in one of our plastic

I used to think overmolding was too complex. The first time I considered it, I was building a small batch of handheld devices. I needed

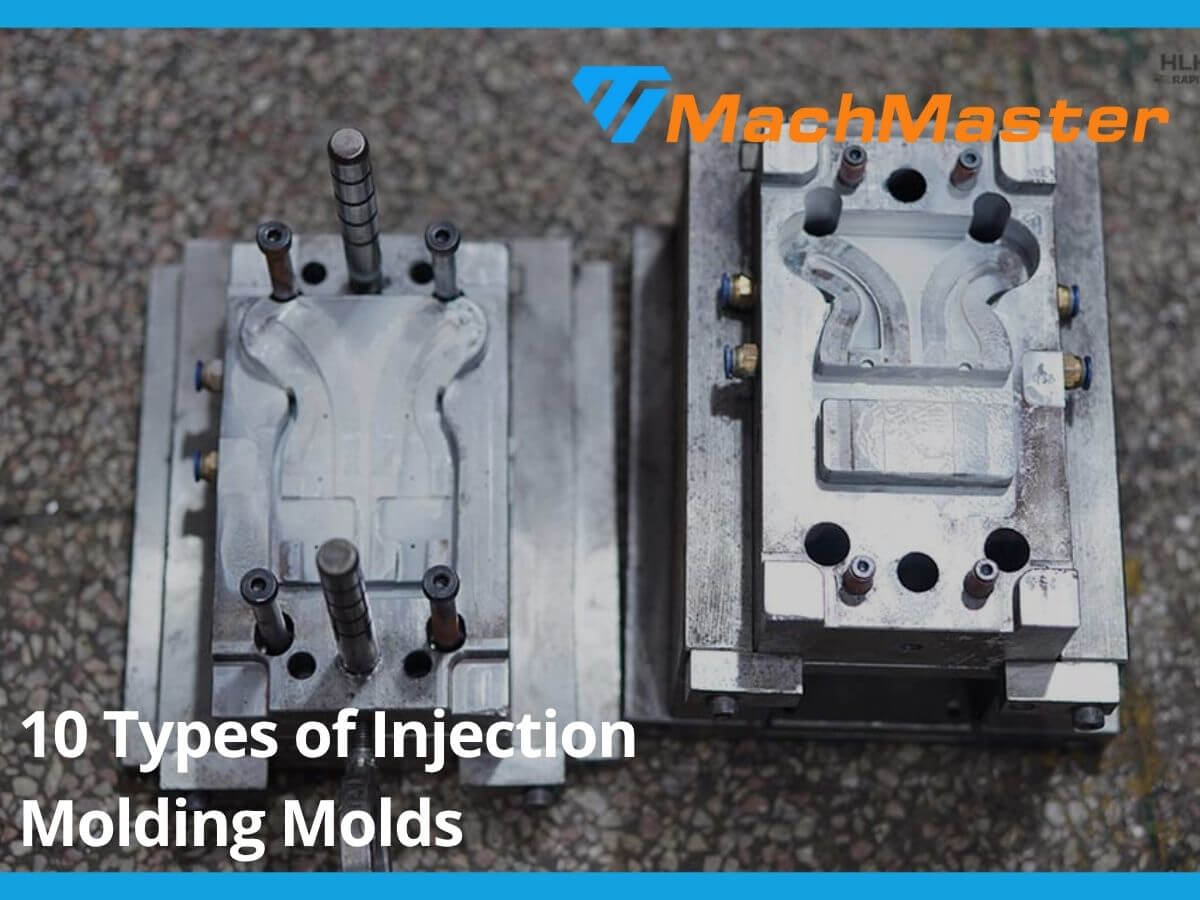

We were in a supplier meeting, looking at mold options and everyone nodded like they understood. I didn’t. I had no clue what a family

I used to “guess” my way through plastic part production. Sometimes it worked. Other times, I ended up with warped parts, long delays, or higher

I remember staring at my inbox, waiting. The prototype was supposed to arrive two days ago. The client was checking in. I had no good

Service

About MachMaster

2026. All Rights Reserved.

WhatsApp us