How Does Die Casting Work

A client sent over their part file. It looked fine. Tight tolerances. Clean geometry. Then the die caster sent it back. “Redesign needed. Won’t release

Explore Our Perspectives on Precision, Innovation, and Manufacturing.

A client sent over their part file. It looked fine. Tight tolerances. Clean geometry. Then the die caster sent it back. “Redesign needed. Won’t release

The client looked at me and asked, “Why are we paying $16 for one part?” And honestly, I didn’t have a good answer. The part

A while back, a client reached out in frustration. Their aluminum parts had just failed inspection for the third time—, and the project was already

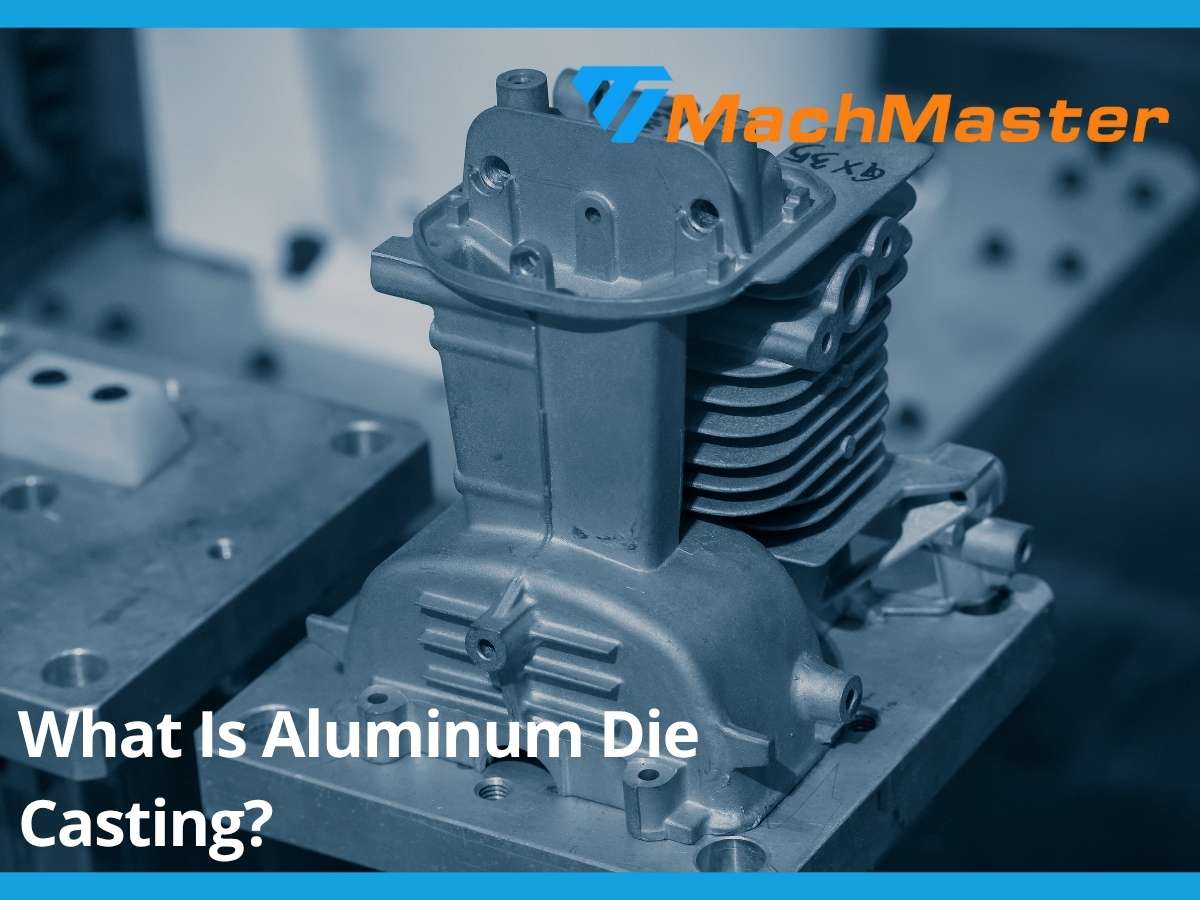

I used to think die casting was overkill. Too expensive. Too specialized. Then I saw what it did for our lighting housings. Stronger parts. Less

I still remember walking into the factory on my first day. The heat hit me first. Then the noise—machines pounding away—and a supervisor rattling off

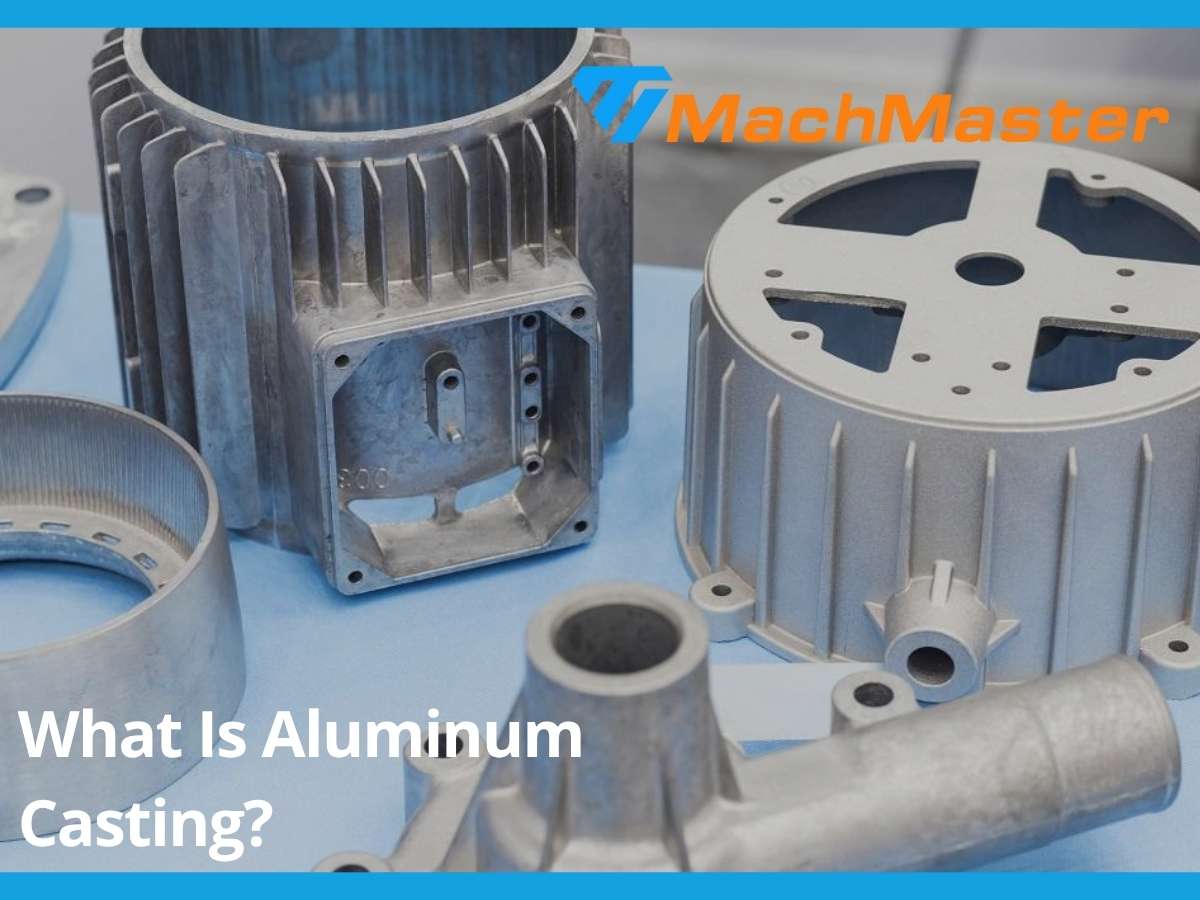

When I first started working in manufacturing, casting felt like a mystery. Everyone talked about it like it was basic knowledge—but no one explained it

The first time someone asked me, “Do you know aluminum die casting?” I nodded. But truthfully? I didn’t. I had a rough idea—but not enough

A few years ago, a new customer came to us with a part they needed fast. The drawings looked solid. The price was good. And

I remember seeing it in a project quote—“cast aluminum.” Then someone said it in a meeting. Everyone else seemed to get it. I didn’t. But

Service

About MachMaster

2026. All Rights Reserved.

WhatsApp us