Case Studies

MachMaster – Bringing Innovation to Life with Precision CNC Machining.

Real-World Applications of Our Parts

Explore how MachMaster components are used across industries—from consumer electronics to custom hardware. These examples highlight the precision, finish, and versatility we bring to every project.

Real Projects, Proven Results

Discover how MachMaster delivers precision, speed, and reliability across real-world manufacturing challenges. From CNC machining to injection molding, our case studies showcase successful collaborations with global customers—backed by data, process transparency, and visual proof.

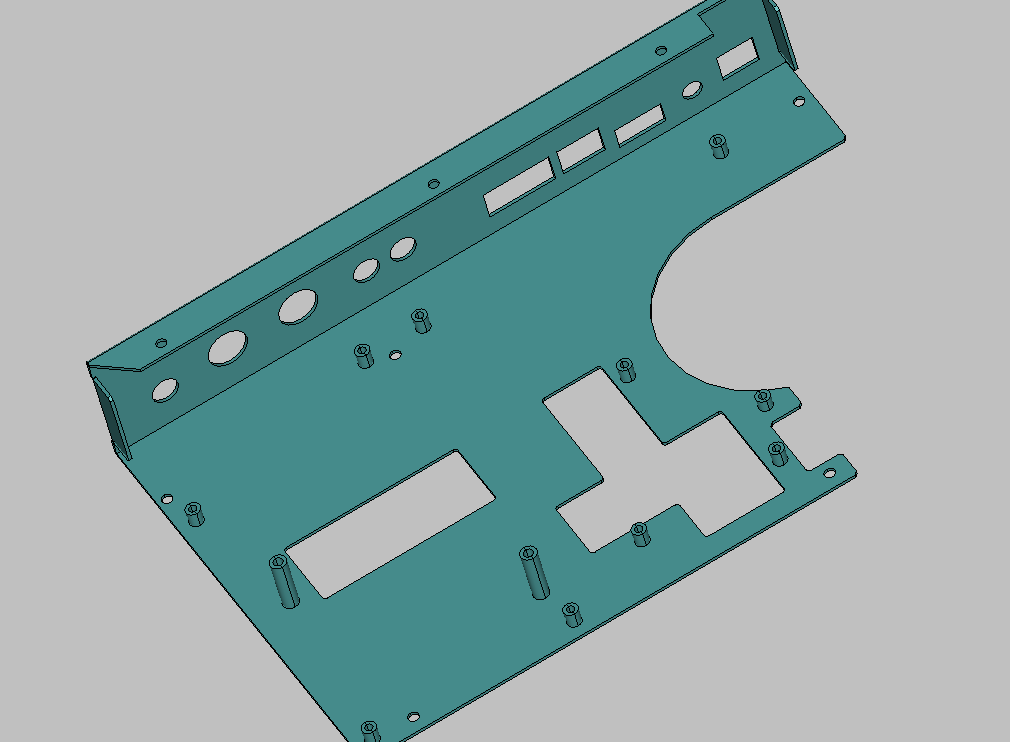

Korean Cycling Brand — Custom Housing for Wireless Bicycle Computer (CNC + Injection Molding)

Client Pain Points

- The client was launching their first bicycle computer product and lacked design-for-manufacturing experience, resulting in structural issues such as snap-fit interference, insufficient boss wall thickness, and button sticking.

- The housing required precise integration of two processes — CNC aluminum shell and injection-molded buttons — with a dimensional tolerance of ±0.05mm.

- Initial samples had assembly issues, delaying the overall development timeline.

- The client was concerned about potential mold failure costs and communication inefficiencies with the supplier.

MachMaster’s Solution

- Provided engineering support to optimize part design, including chamfers on aluminum parts, snap-fit tuning, and tightening tolerance zones.

- Adopted a hybrid manufacturing strategy: high-precision CNC machining for the aluminum body and injection molding for ABS buttons, all aligned with a unified assembly datum.

- Delivered CNC-milled prototypes within 5 days to validate fit and structure, while mold design was initiated in parallel.

- Assigned a dedicated project manager to oversee CNC, molding, and anodizing workflows — ensuring seamless communication and tight timeline control.

- Applied anodizing to the aluminum shell, with color variation controlled under ΔE < 1.5 for consistent aesthetics.

Final Results

- Functional prototypes delivered in 5 days; mold and mass production completed within 30 days.

- Assembly went smoothly; button feel and fit exceeded expectations — client called it “more professional than expected.”

- The client initiated two follow-up projects in the same product line and recommended MachMaster to their upstream bike brand partner.

- Established a complete cooperation loop from design optimization to production delivery, with plans for long-term strategic partnership.

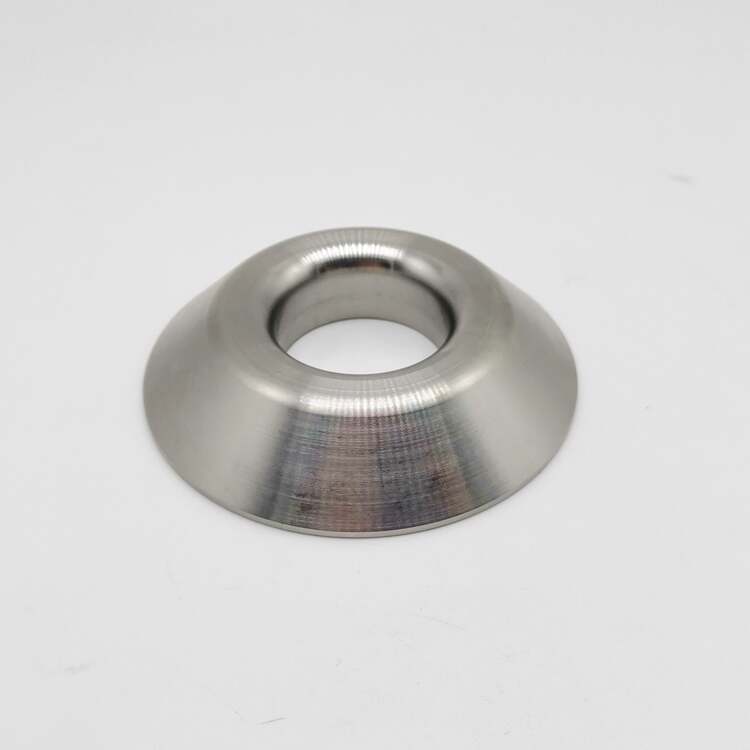

American Pool Equipment Innovator — Hybrid Manufacturing for Leak-Proof ABS Seal Components

Client Pain Points

- O-ring groove surface at parting line caused micro-irregularities (<0.1mm), resulting in premature seal wear and >30% leakage

- Traditional solutions like metal machining were too expensive (+200% cost), while modifying the parting line would require full mold remanufacturing

- Client needed a reliable fix that didn’t break the budget or extend lead time

MachMaster’s Solution

- Re-engineered the mold to oversize the groove by +0.5mm, enabling precision CNC turning to fine-tune the sealing surface

- Applied CNC turning with ceramic tools at 3000 RPM, achieving Ra 0.8μm surface roughness

- Delivered 5 CNC-modified samples within 72 hours for real-world validation

- Implemented hybrid manufacturing: injection molding for body, CNC finishing for groove

Final Results

- Client verified 6-month continuous leak-free operation at 3m underwater

- Reduced per-unit cost by 39.5% and mold revision cost by 90%

- Client re-ordered 3 additional batches totaling 4,000 units

- Solution later applied in automotive, medical, and outdoor lighting products

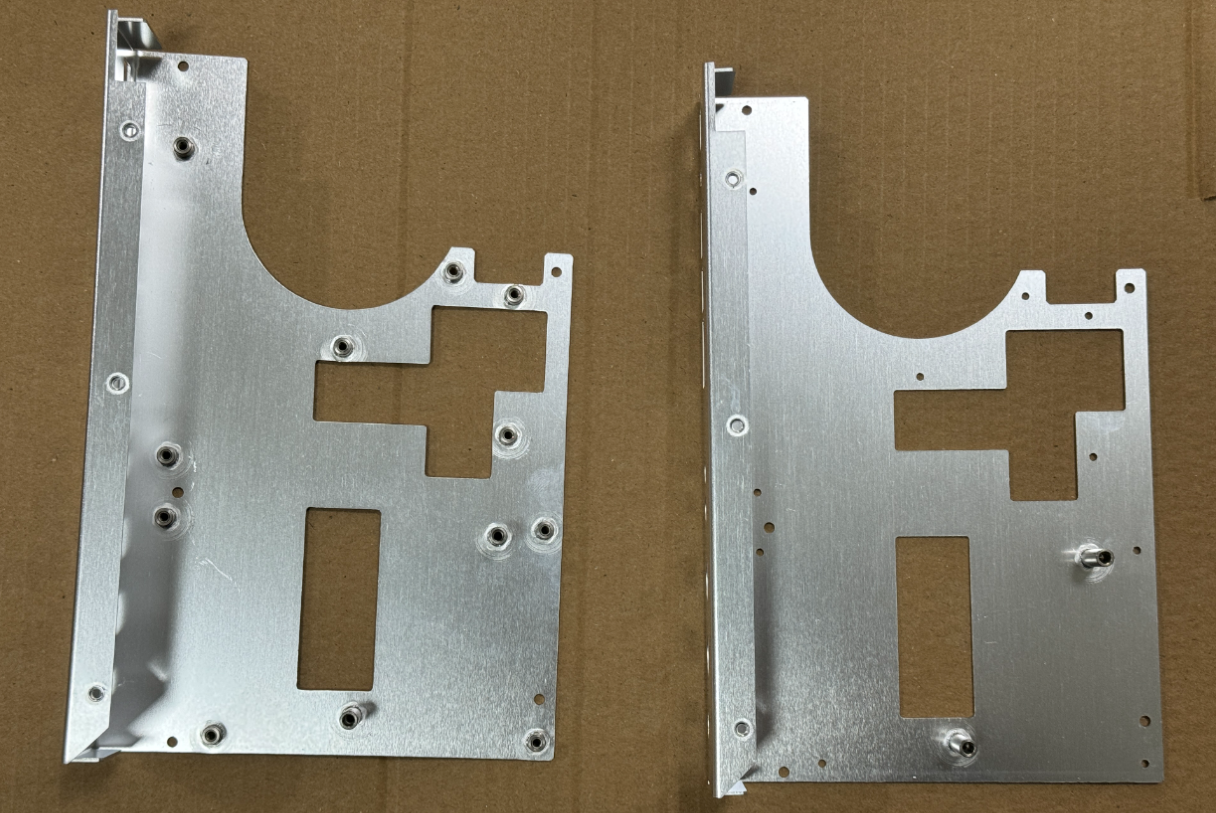

Korean Electrical Enclosure Maker Resolves Riveting & Bending Conflict

Client Pain Points

- Stainless steel rivets couldn’t be pressed after bending

- Pressing them first blocked anodizing

- Design layout left no room for mechanical sequence adjustment

MachMaster’s Solution

- Switched to aluminum rivets (anodize-compatible)

- Rivets pre-installed before bending

- Problematic narrow sections redesigned and welded

- Ensured anodized surface integrity post-processing

Final Results

- Seamless fit and finish

- Avoided mold rebuild and reduced total cost

- approved for future batch orders

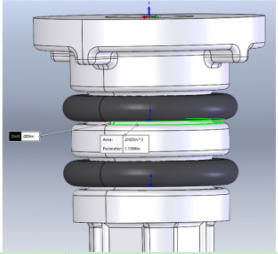

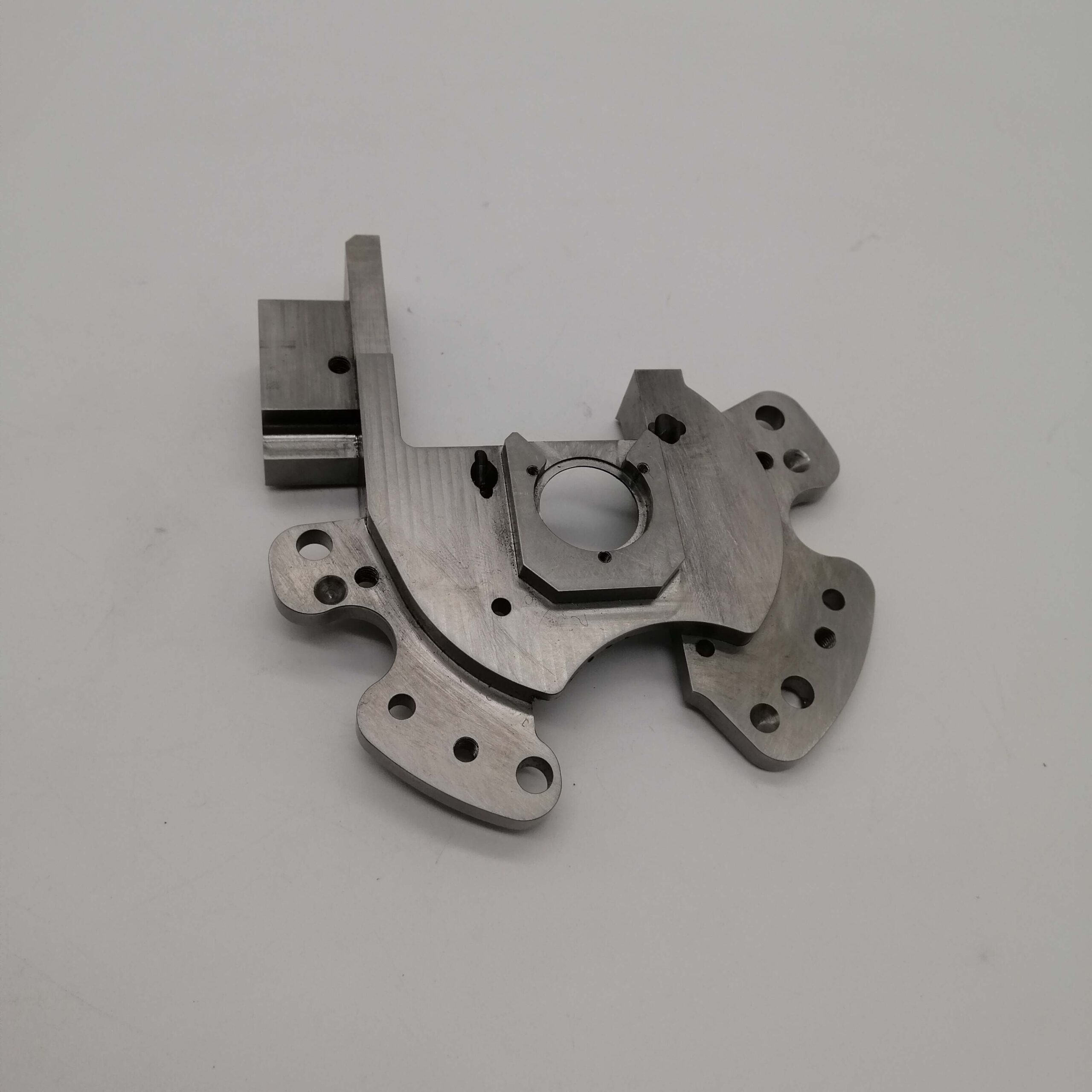

Korean Aerospace Components Supplier — Titanium Alloy Precision CNC Parts

Client Pain Points

- Rapid tool wear with titanium

-

Surface roughness failed

- Dimensional drift due to machine vibration

MachMaster’s Solution

- Customized tool geometry with supplier partnership

- Designed interDynamic machine calibration + multi-stage cuttingnal reinforcing flanges to prevent warping

- High-pressure coolant and finishing passes

- Final tuning on finishing parameters

Final Results

- Surface finish Ra 0.4μm (titanium), Ra 0.2μm (aluminum)

- Accuracy stable at ±0.02mm, <1% scrap rate

- Follow-up orders confirmed for advanced parts

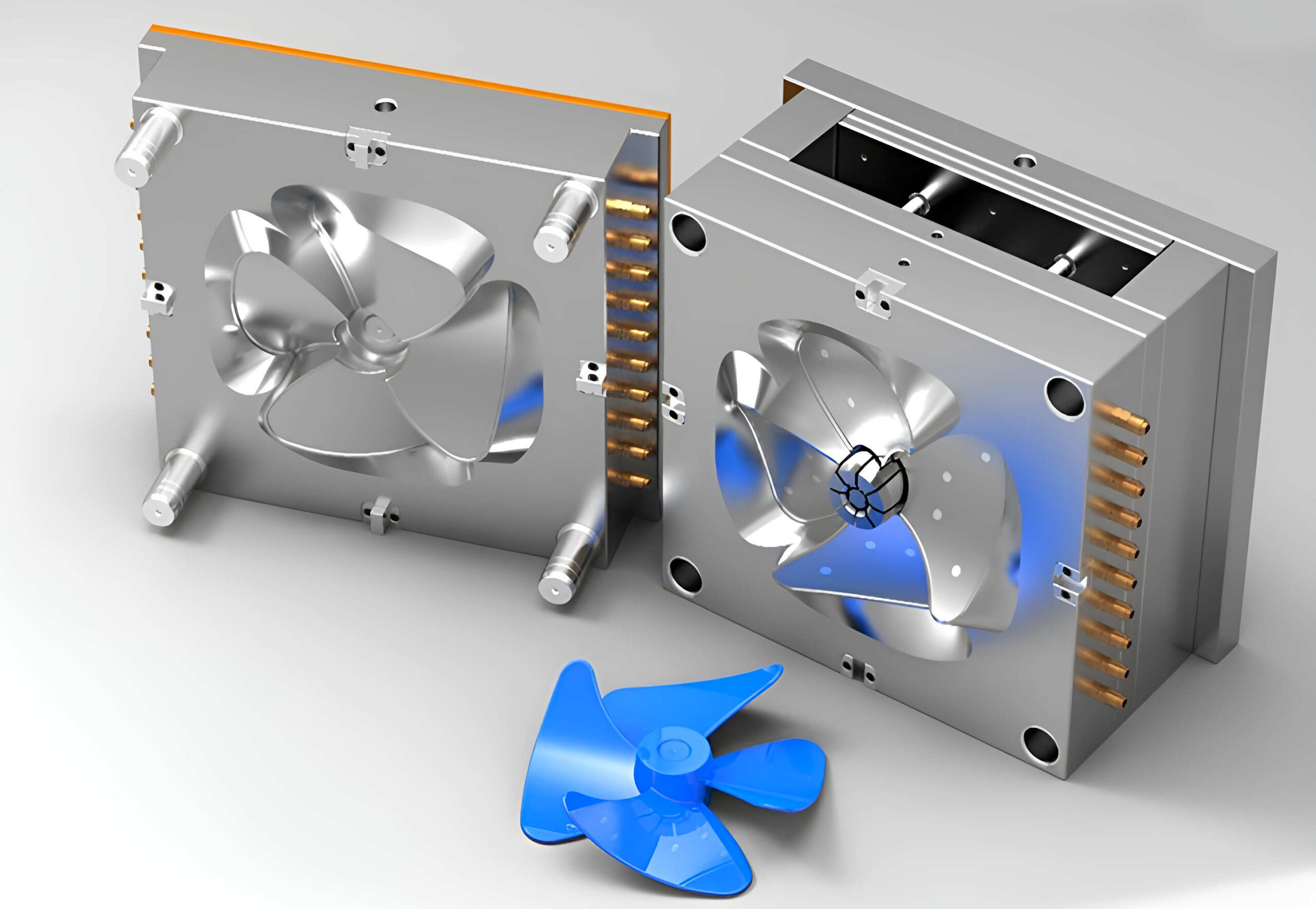

Consumer Bathroom Product — Optimizing Mold & Process for Cosmetic Plastic Part

Client Pain Points

- Flow marks, air marks lowered yield (30%)

- Poor dimensional fit, deformation under humidity

- Structural stress led to cracks in functional use

MachMaster’s Solution

- Hot runner needle valve system improved fill balance

- Conformal cooling channels increased mold temp control

- DOE-based parameter tuning for injection curves

- Material modification for anti-shrink and anti-gloss defects

Final Results

- Surface defect rate dropped to <10%

- Structural integrity passed moisture resistance test

- Yield improved to >90%, accepted for series production

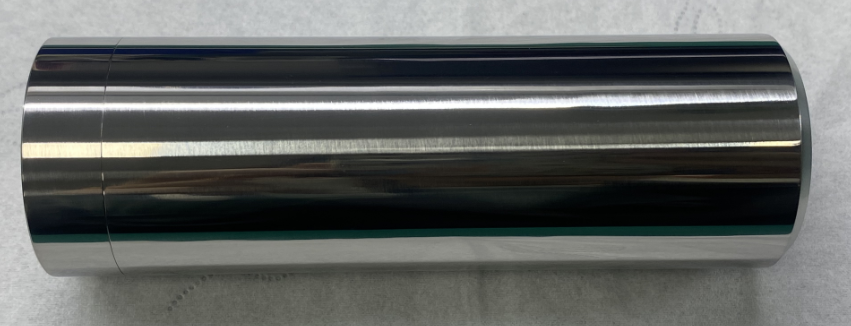

High-End Labware Product — Precision Machined Stainless steel Case with Protective Packaging

Client Pain Points

- Surface scratches >15%, rework rate >30%

- Packaging failed to protect mirrored finish

- Brightness rating below visual standard (69%)

MachMaster’s Solution

- Used PCD diamond tools for ultra-smooth finish

- Added 1000-grit polishing wheel post-machining

- Introduced 5-layer packaging (foam, tray, sleeve)

- Lighting-based QC for brightness and visual grading

Final Results

- Surface defect rate reduced to 0.3%

- Brightness pass rate increased to 99.7%

- 95% reduction in total rejections

- MachMaster approved as long-term supply partner

Manage Your Machining Needs with MachMaster

Capabilities That Set Us Apart

Precision, efficiency, and reliability—these are the qualities that define how we work and what our customers value most.

High Precision

Achieve tight tolerances down to ±0.01mm for demanding parts and applications.

Fast Production

Short lead times for prototypes and large orders, with consistent quality throughout.

Material Flexibility

Compatible with metals and plastics, from simple shapes to complex parts.

Engineering Support

Get design-for-manufacturing advice and full technical guidance throughout your project.

Quality Control

Every part is inspected to meet strict standards and ensure consistent performance.

Manufacturing Experience

Over two decades of hands-on production across industries and part complexities.

Why Customers Choose MachMaster

Clear results, responsive service, reliable delivery—see why so many choose to work with us.

Tell Us What You Need

At MachMaster, our engineers review every request and respond with tailored solutions.

Your files are kept strictly confidential and will only be used for quoting and manufacturing purposes.

- info@machcncmaster.com

- +86 139 5006 6486