Custom CNC Machining Services For Aluminum

MachMaster delivers high-precision aluminum parts with excellent strength-to-weight ratio, corrosion resistance, and machinability—ideal for aerospace, automotive, and consumer products.

Material Description

Aluminum is a popular choice for machining due to its low density, good mechanical properties, high thermal and electrical conductivity, and resistance to corrosion. Aluminum alloys, such as 6061, 5052, 5083, 6061-T6, 6063, 6082, 7075, 7075-T6, and 2024-T351, are commonly used in CNC machining because they offer a good balance of strength, machinability, and cost. Aluminum alloy has gradually become the preferred choice for both clients and manufacturers.

Advantages of Aluminum

- Excellent machinability

- High strength and hardness

- Heat tolerance and corrosion resistance

- Electrical conductivity

- Good thermal conductivity

Wide Application of Aluminum

aluminum is a broadly used metal in many industries, including automotive, defense, aerospace, transportation, construction, packaging, electronics, consumer goods and more.

- Automotive parts (light-weighting provides high strength-to-weight ratio)

- Housing, brackets, and other components for aerospace use that must support heavy load capacities but be light weight

- Fixtures, calipers, and a variety of other parts for industrial equipment

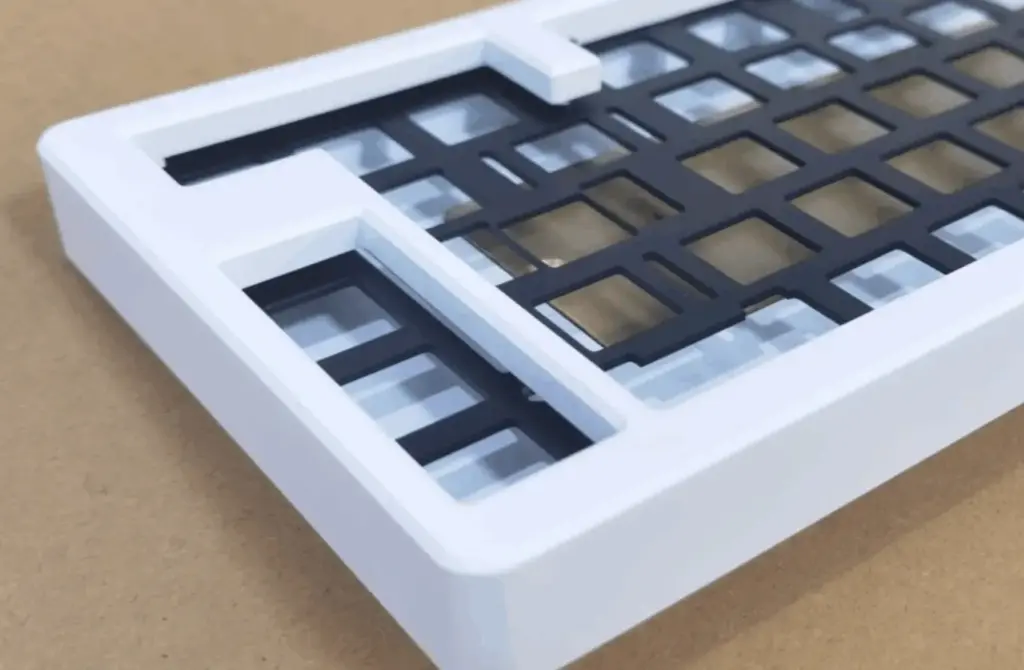

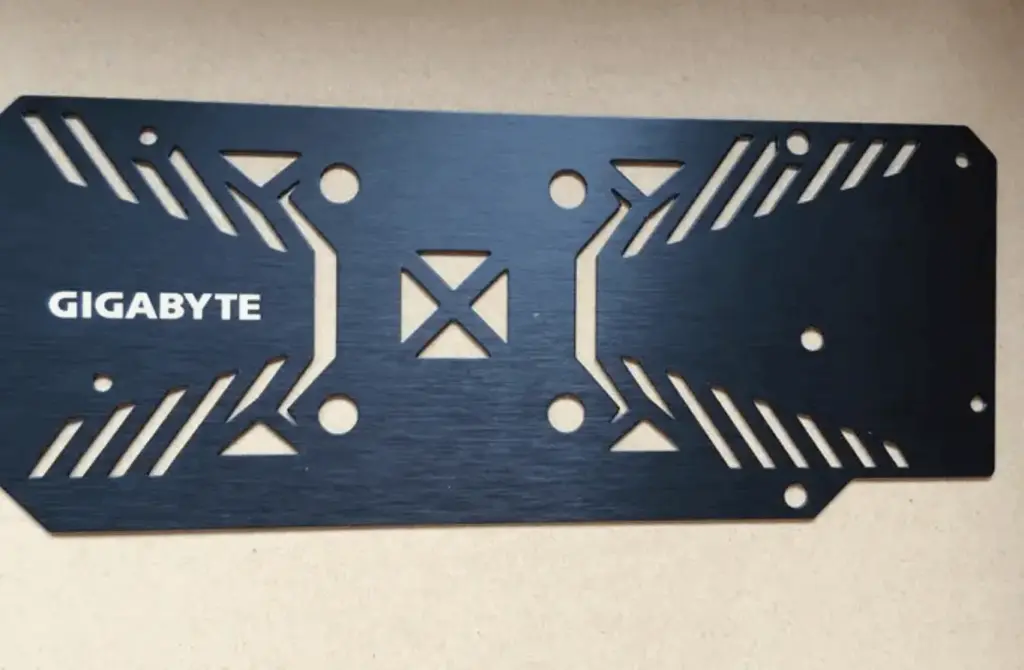

- Enclosures, panels, consoles, knobs, housing, and other applications for consumer and computer electronics

Aluminum Model Classification

MachMaster offers a variety of aluminum alloys for you to choose from

Aluminum 7075 T651 and T7: Benefits include high strength, hardness, low weight, corrosion resistance, and high heat tolerance.

Aluminum 2024 T3: This high-strength alloy offers a high strength-to-weight ratio and high corrosion resistance.

Aluminum 6061 T651: Though not as strong as other types of Aluminum, this alloy offers the best corrosion resistance and appearance after anodizing.

Manage Your Machining Needs with MachMaster

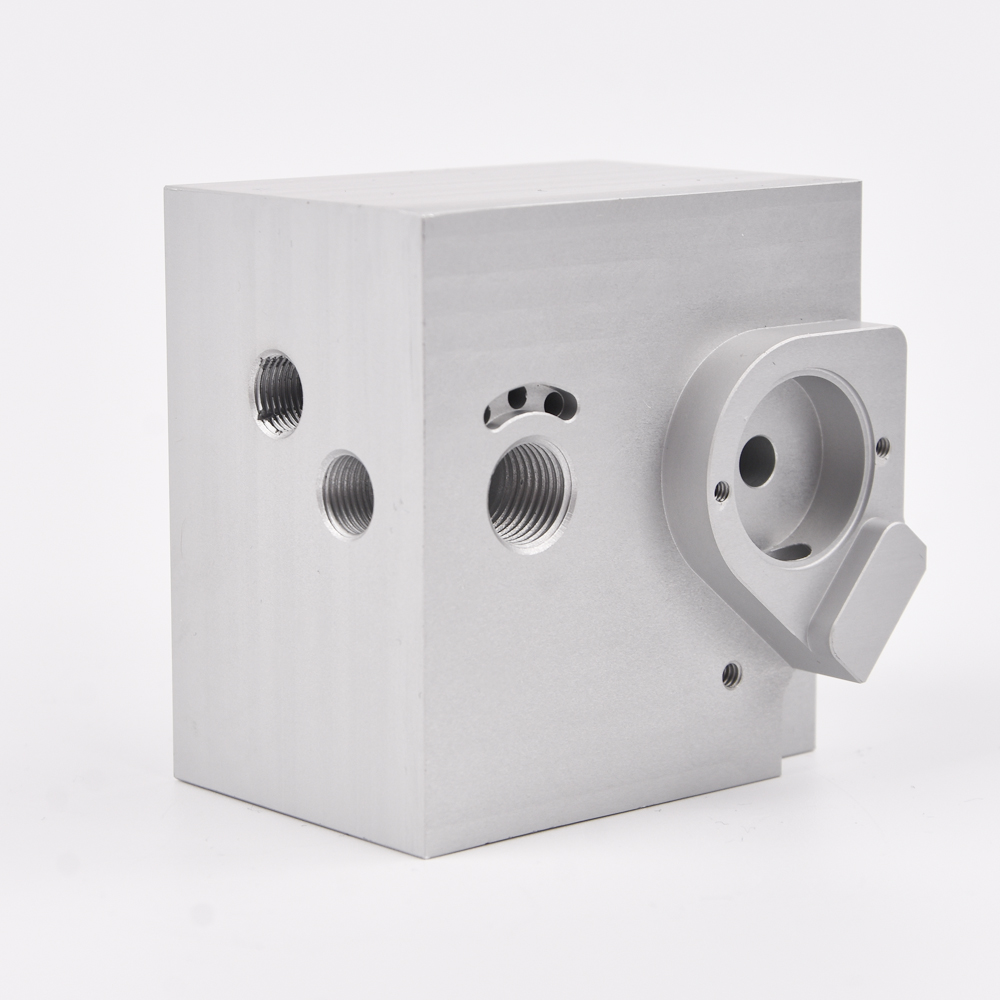

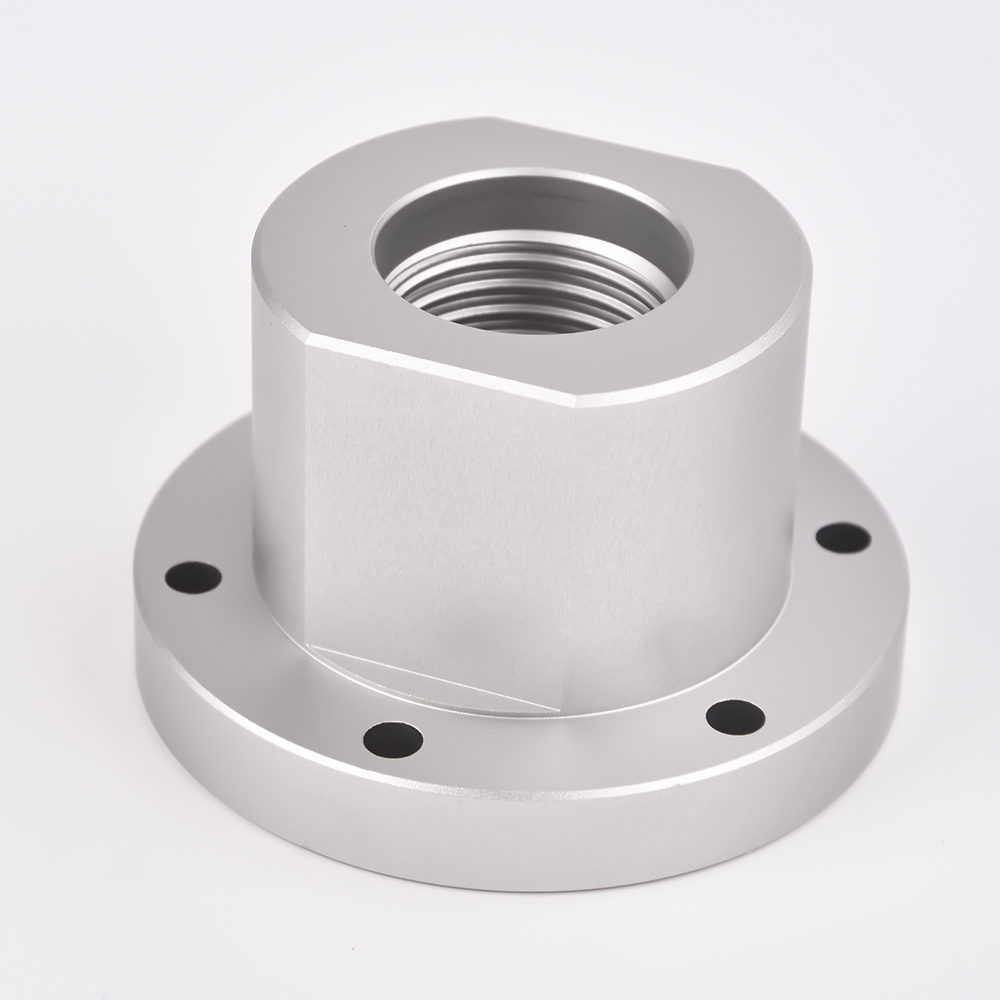

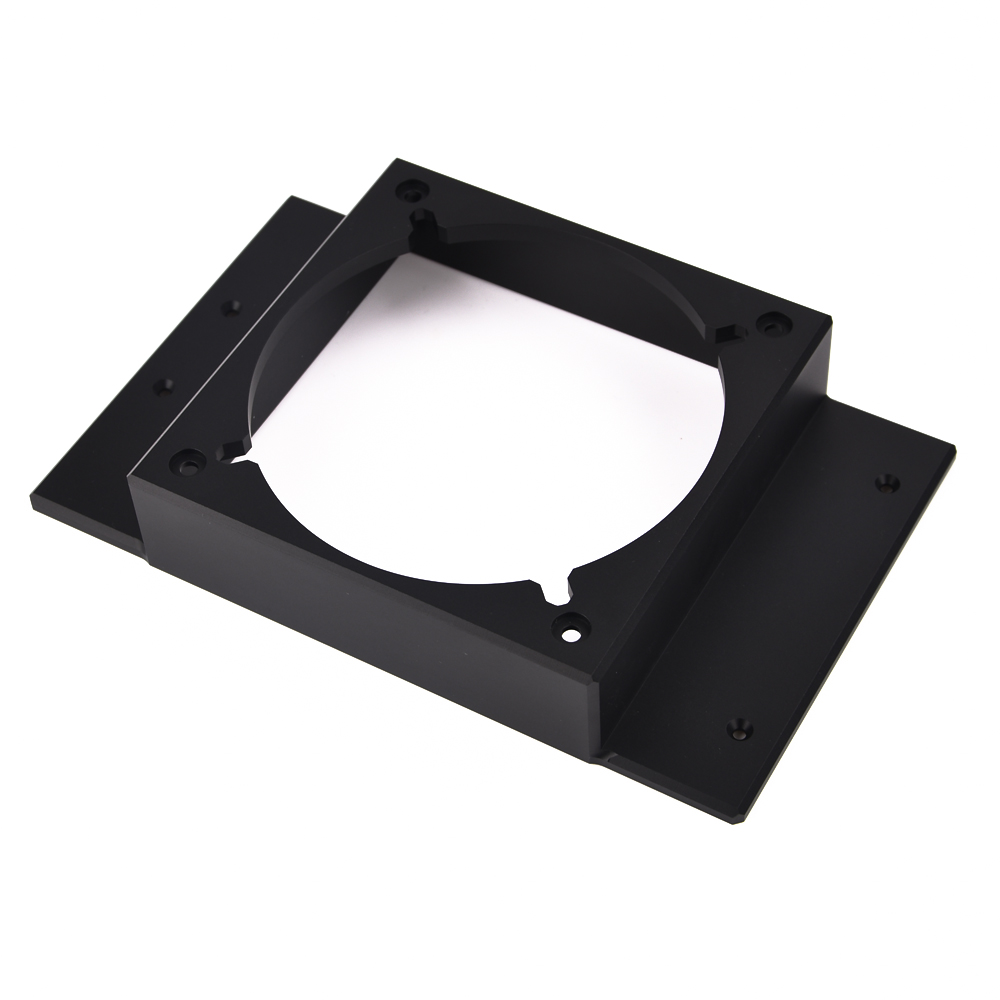

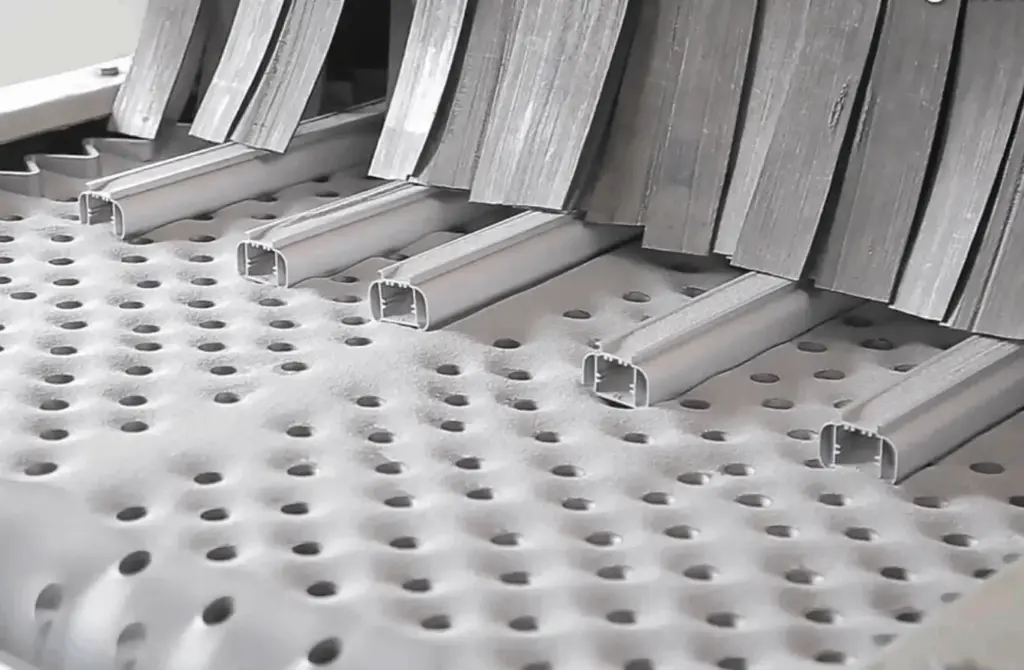

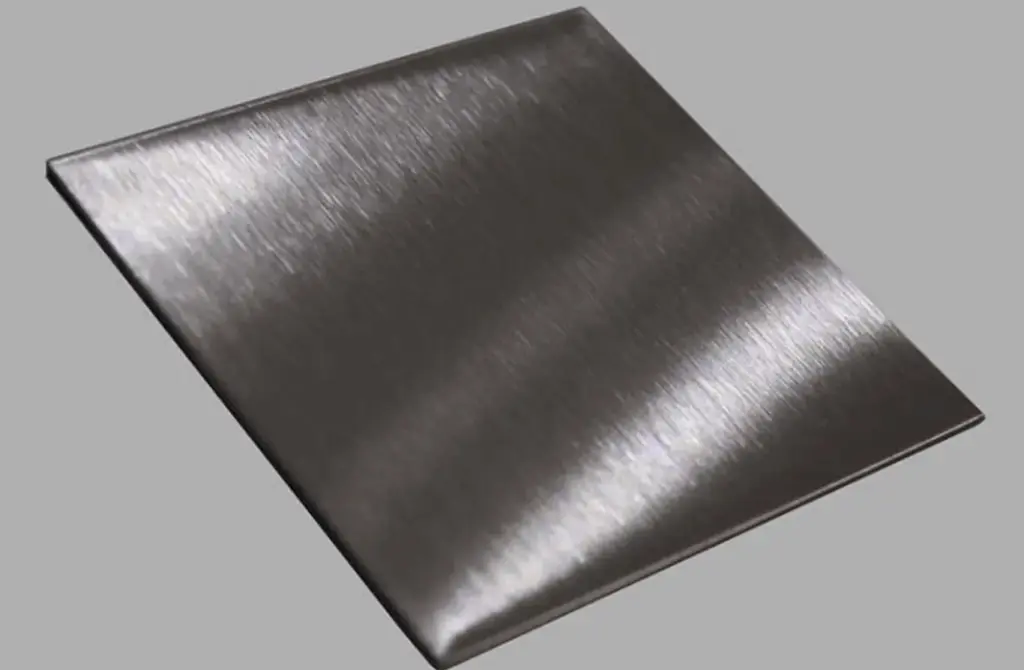

CNC Machined Aluminum Parts Gallery

These aluminum parts are manufactured by CNC milling and turning, and finished with sand blasting and anodizing.

Explore Our CNC Aluminum Materials

Discover our Aluminium CNC milling service for all your precision machining requirements. Please have a look at some of our premium materials to identify what best suits your project.

| Material | Description |

|---|---|

| Aluminum Alloy 6061-T6 | DIN EN 3.3211 | UNS A96061 | AlMg1SiCu | In terms of its strength-to-weight ratio, machinability, and resistance to corrosion, nothing beats the aluminum 6061 (CNC) among other aluminum alloys. This material does not stick to magnets and can hardly be eroded by rust. |

| Aluminum 7075-T6 Alloy | DIN 3.4365 | Lightweight & High Strength | AlZn5.5MgCu | 7075-T6 aluminum, a first-class aerospace material, is characterized by an impressive strength-to-weight ratio equal to that of steel. This CNC aluminum is not magnetic and, therefore, can be used for different purposes. |

| Aluminum Alloy 6060 | Grade 3.3206 | AlMgSi | Alloy 6060: Gives strong build quality, fair corrosion resistance and ideal for decorative anodizing. Great for metal applications. |

| Aluminum Alloy 6082 (3.2315) - AlSi1MgMn | Material Specification and Properties | The tensile strength of aluminum 6082 (CNC) is slightly higher than that of 6061. It is composed of the same materials and has similar properties to the latter; however, it meets British Standards by being both corrosion-resistant and non-magnetic, thus making it perfect for many uses. |

| Aluminum Alloy 5083-H111 | 3.3547 | 54300 | AlMg4.5Mn0.7 | Aluminium 5083 (CNC) is a type of aluminium that possesses great strength and can be used in corrosive environments. It is commonly known as an alloy with excellent corrosion resistance properties, making it perfect for marine applications. This metal is non-magnetic and has the ability to be easily joined together by welding. |

| Aluminum Alloy 6063 | EN AW-6063 | 62400 | AlMg0.7Si. | Aerospace applications are why aluminum 6063 is said to have excellent mechanical properties and be heat treatable. Besides, it can also be welded. This metal is adaptable and has many applications in different fields.Decorative anodizing. |

| Aluminum Alloy 5052 (EN AW-5052) - AlMg2.5 - Grade 3.3523 | The amazing thing about Aluminum 5052 is that it’s a top-notch, high-strength aluminum alloy with excellent corrosion resistance. It can be used for marine applications because of this property among others. Being highly versatile in nature, the material also allows for welding which gives it strength and durability needed in different areas. |

| Aluminum Alloy 2024-T351 | ASTM B209 | High Strength | Aerospace Grade | The aluminum 2024 is a highly potent compound famous for its outstanding fatigue resistance, which makes it suitable for aerospace uses. This material is very tough and works well in harsh conditions. |

| Aluminum Alloy 7050 | EN AW-7050 | AlZn6CuMgZr | Material 3.4144 | For aerospace applications, Aluminum 7050 is considered as one of the best materials due to its great mechanical properties such as ductility combined with high strength, toughness and fatigue resistance. |

| Aluminum MIC6 Plate: Properties, Uses, and Benefits | Aluminum, specifically MIC6, is a lightweight material that can be used for high-speed machining; it has low stress levels as well as being clean and free from porosity. This makes it perfect for accurate metalwork. |

| Aluminum Alloy 6082-T651 | Grade 3.2315 | UNS A964430 | Aluminium Silicon Magnesium Manganese | Closely composed and having almost the same characteristics as 6061 aluminum, Aluminum 6082-T651 (CNC) however has a bit higher tensile strength than the former. It is British Standards compliant which makes it widely used in the metalworking sector because of its reliability. |

| Aluminum Alloy 2017A - Grade 3.1325 | Tensile Strength: 24530 psi | Alloy Composition: AlCu4MgSi | When it comes to strength, Aluminum 2017 is not as strong as Aluminum 2014 but the former has better malleability and workability. |

| Aluminum Alloy 7075-T651: A High-Strength Option for Diverse Applications | 7075-T651 (CNC) aluminum is a good metal for making airplane parts. It has an excellent strength-to-weight ratio, which can be matched with steel. After stress relieving, the T651 temper is obtained by solution heat treating it and then aging it artificially. This aerospace-grade aluminum alloy is widely used in the industry because of its high hardness and potent properties. |

| Aluminum Alloy 2014 | Grade 3.1255 | Part Number 24345 | Composition: AlCu4SiMg | Aluminum in 2014 is a versatile metal that has the same machinability and strength as steel, but it can be corroded easily. It is used widely in the aerospace industry because of its properties. |

| Aluminum Alloy 6061-T651: A Versatile Option with Excellent Strength and Corrosion Resistance | High strength, excellent machinability, and easy welding make 6061-T651 aluminium a widely used material in the aerospace, automotive, and construction sectors. The “T651” classification is given to materials that have been heat treated at an exact temperature for a specific hardness range. |

| Aluminum Alloy 7075-T7351 | DIN 3.4365 | AMS 76528 | AlZn5.5MgCu | Aluminum 7075-T7351 is widely used in aerospace, defense, automotive, and transportation industries due to its high strength, good machinability, and fatigue resistance. The indication “T7351” means that it was hardened to a certain level by heat treatment. |

Aluminum Alloy Properties Overview

| Aluminum Type | Temper | Ultimate Tensile Strength (ksi) | Elongation (%) | Hardness (HRB) |

|---|---|---|---|---|

| 2024 | T351 | 68 | 19 | 120 |

| 5052 | H32 | 33 | 18 | 60 |

| 7075 | T651 | 83 | 11 | 150 |

| 6061 | T651 | 45 | 17 | 95 |

Finishing Options for CNC Machining

From improved corrosion resistance to refined aesthetics, surface finishes are essential for CNC machined parts. We offer a variety of finishing options—such as anodizing, powder coating, polishing, and electrophoretic coating—each tailored to enhance durability, function, or appearance depending on your application needs.

Anodizing

Electrochemically forms a dense aluminum oxide layer on the surface to enhance corrosion and wear resistance. It can be dyed in various colors such as black, gold, red, and clear.

Electrophoretic Coating

Applies a uniform paint film through an electric field to improve surface corrosion resistance and visual appeal. The result is smooth, even, and protective.

Powder Coating

A dry powder is electrostatically sprayed onto the surface and then cured at high temperature, forming a durable, weather-resistant finish available in a variety of colors.

Polishing

Mechanical or chemical processes remove oxidation and micro-defects to produce a smooth, mirror-like surface—ideal for decorative and functional parts.

Sandblasting

High-speed abrasive particles are blasted onto the surface to remove oxide layers and residues, increase roughness, and enhance adhesion for subsequent coatings.

Brushing

Creates fine, directional textures using abrasive belts or brushes to achieve a matte, decorative finish with a consistent grain pattern.

Electroplating

Deposits a thin layer of metals like nickel, chrome, or copper on the aluminum surface to improve corrosion resistance, wear performance, or achieve a distinct appearance.

Laser Engraving

Uses precise laser technology to mark logos, text, or patterns on the aluminum surface—offering permanent, high-contrast, and aesthetic results.

Capabilities That Set Us Apart

Precision, efficiency, and reliability—these are the qualities that define how we work and what our customers value most.

High Precision

Achieve tight tolerances down to ±0.01mm for demanding parts and applications.

Fast Production

Short lead times for prototypes and large orders, with consistent quality throughout.

Material Flexibility

Compatible with metals and plastics, from simple shapes to complex parts.

Engineering Support

Get design-for-manufacturing advice and full technical guidance throughout your project.

Quality Control

Every part is inspected to meet strict standards and ensure consistent performance.

Manufacturing Experience

Over two decades of hands-on production across industries and part complexities.

FAQs About CNC Aluminum Machining

What Aluminum Grades Are Commonly Used in CNC Machining?

Grades like 5052, 6061, 7075, and 2024 are widely used due to their balance of strength, machinability, and corrosion resistance. The choice depends on application needs such as structural load or surface finish.

Can Machined Aluminum Parts Be Anodized?

Yes, anodizing is a common surface treatment for aluminum parts after machining. It enhances corrosion resistance, allows coloring, and improves surface durability.Machmaster has its own anodizing workshop, ensuring better quality control.

How Does Aluminum Grade Affect Machinability and Cost?

Higher-strength grades like 7075 offer better performance but can be harder to machine and more costly than 6061. Material selection should match both functional and budget priorities.

What Should I Consider About Cost in CNC Aluminum Projects?

Costs depend on material grade, part geometry, tolerance, surface finish, and volume. Simple parts in 6061 cost less than complex parts in 7075 with tight tolerances.

What’s the Difference Between Machining 6061 and 7075 Aluminum?

6061 is easier to machine and anodize, while 7075 provides superior strength and wear resistance. Each suits different end-use scenarios—from general parts to aerospace applications.

How Does MachMaster Speed Up Aluminum Part Production?

With in-house CNC machines, fast DFM feedback, and streamlined quoting, we reduce lead times from days to hours—ideal for rapid prototyping or low-volume production.

Tell Us What You Need

At MachMaster, our engineers review every request and respond with tailored solutions.

Your files are kept strictly confidential and will only be used for quoting and manufacturing purposes.

- info@machcncmaster.com

- +86 139 5006 6486