About

Decades of Precision, Focused on Every Detail.

Jason Dong's Vision: Building Trust Through Precision

Founder of MachMaster

I started in precision manufacturing over 30 years ago, and I’ve seen firsthand how difficult it can be for overseas teams to find a supplier who’s both technically reliable and easy to work with. That’s why I founded MachMaster in 2013—not just to make parts, but to support international clients with engineering-driven, multi-process manufacturing they can count on.

Our team combines CNC machining, injection molding, and finishing services under one roof, with a clear focus on speed, communication, and quality. I still get involved in complex projects when needed—not for control, but because I believe in what we promise: no overpromising, no surprises, and full accountability.

If you need a supplier who understands what matters beyond the spec sheet, we’d be glad to work with you.

Speed Meets Precision at MachMaster

See our team, process, and precision in action at Xiamen MachMaster Co., Ltd—where every part is backed by expertise, systems, and measurable results.

MachMaster Milestones

From a small workshop in 2002 to a smart factory serving global brands—every step in MachMaster’s journey reflects our commitment to precision, innovation, and long-term partnerships.

1999 – Craftsmanship Begins with Passion

Founder Jason entered the machining industry, gaining hands-on experience in design and production. His passion for precision manufacturing took root and set the course for the company’s future.

2002 – Brand Founded, Focus on Manufacturing

MachMaster was officially established, focusing on CNC machining and mold fabrication to deliver high-quality custom metal and plastic components for a wide range of industries.

2013 – Structure Consolidated, System Shaped

The company consolidated its legacy teams and operations, forming structured product lines and quality systems — a key step toward providing comprehensive manufacturing services.

2015 – Management Upgraded, System Optimized

To support increasing project volume and complexity, MachMaster upgraded its internal operations — refining production workflows, standardizing procedures, and enhancing coordination across the supply chain.

2019 – Capacity Expanded, Delivery Accelerated

The factory expanded from 800㎡ to 2,500㎡ with 50 machines, significantly improving production capacity and response speed to meet growing customer demands.

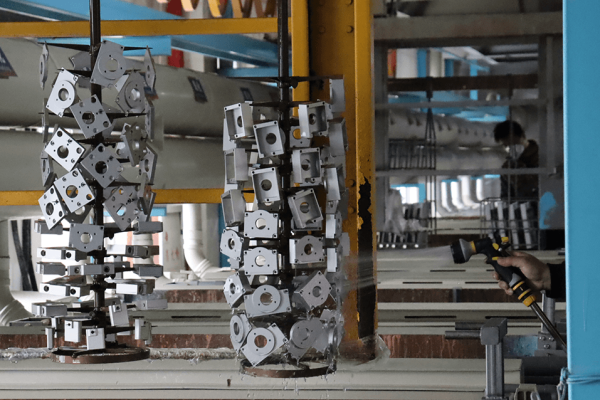

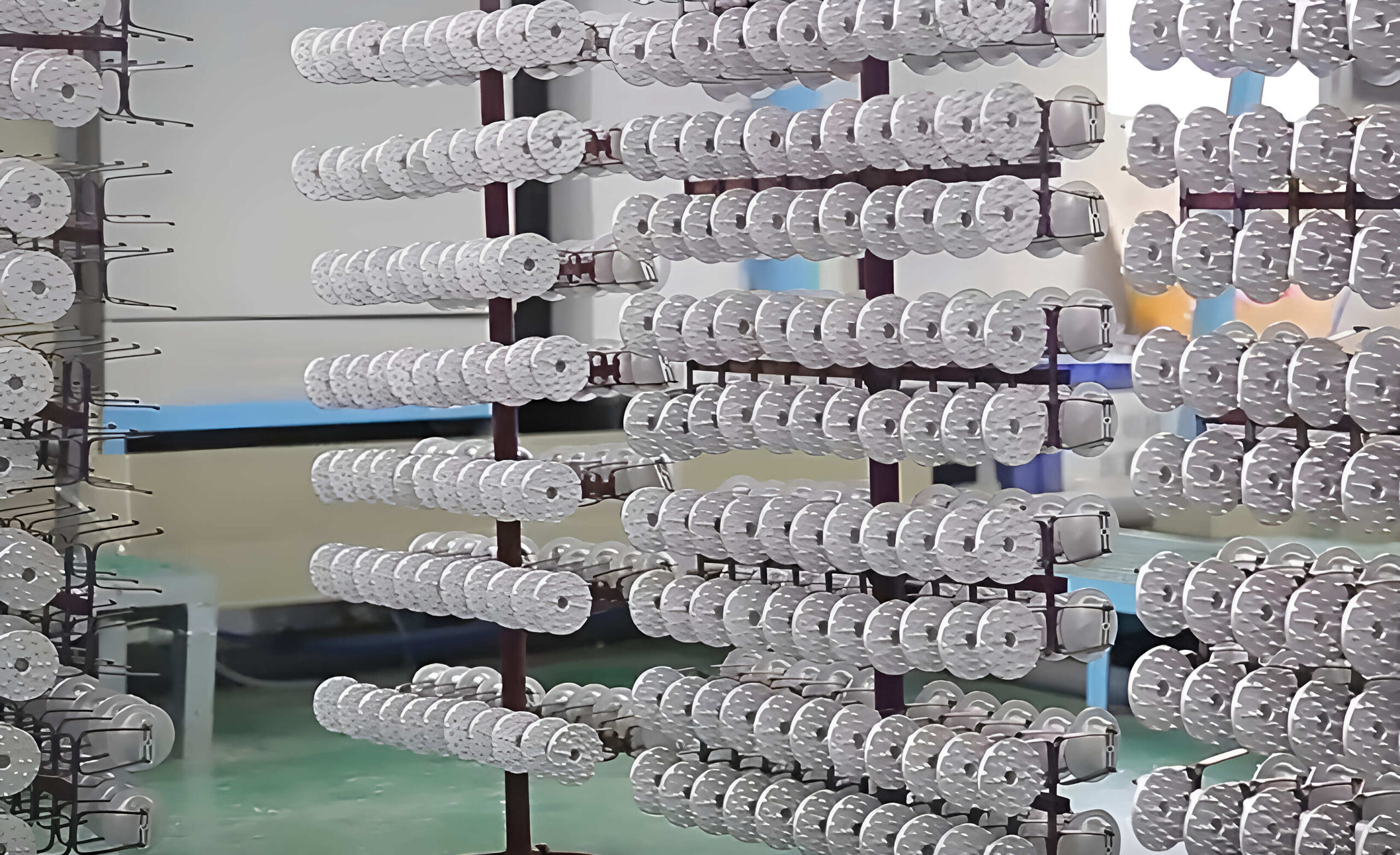

2021 – Factory Upgraded, Added Anodizing Factory (2,000㎡)

MachMaster scaled up to a 4,500㎡ facility with 70 machines and established four core workshops — molds, injection molding, CNC machining, and surface finishing — enabling full one-stop custom manufacturing.

Manage Your Machining Needs with MachMaster

Factory Overview & Capabilities

Built by Experts, Backed by Process

At MachMaster, every project is supported by a dedicated team of experts across engineering, production, quality control, logistics, quoting, and customer support. Through integrated collaboration and precise process management, we ensure consistent quality, reliable delivery, and exceptional service at every stage of your project.

Project & Quotation Team

Manages files, RFQs, and lead time tracking with 24h quoting.

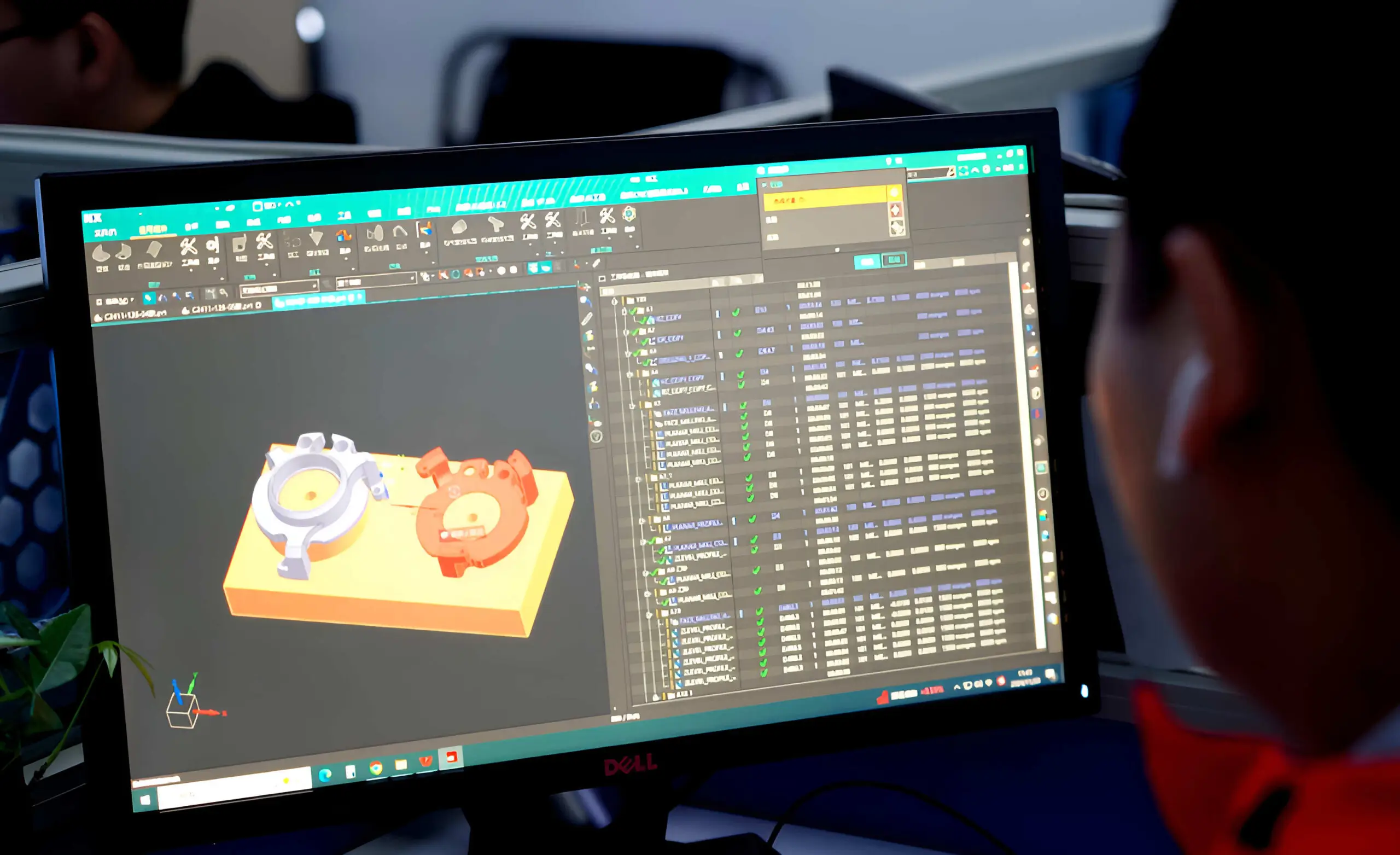

Engineering Team

Provides DFM analysis and technical solutions from design review to production readiness.

Production Team

Runs CNC, molding, casting, and finishing with precision and process control.

Quality Control Team

Handles inspection at every stage with full traceability and ISO standards.

Packaging & Logistics Team

Customizes packaging and ensures safe delivery with accurate scheduling.

Customer Support Team

Handles progress updates, feedback, and after-sales issues with fast response.

Capabilities That Set Us Apart

Precision, efficiency, and reliability—these are the qualities that define how we work and what our customers value most.

High Precision

Achieve tight tolerances down to ±0.01mm for demanding parts and applications.

Fast Production

Short lead times for prototypes and large orders, with consistent quality throughout.

Material Flexibility

Compatible with metals and plastics, from simple shapes to complex parts.

Engineering Support

Get design-for-manufacturing advice and full technical guidance throughout your project.

Quality Control

Every part is inspected to meet strict standards and ensure consistent performance.

Manufacturing Experience

Over two decades of hands-on production across industries and part complexities.

Tell Us What You Need

At MachMaster, our engineers review every request and respond with tailored solutions.

Your files are kept strictly confidential and will only be used for quoting and manufacturing purposes.

- info@machcncmaster.com

- +86 139 5006 6486