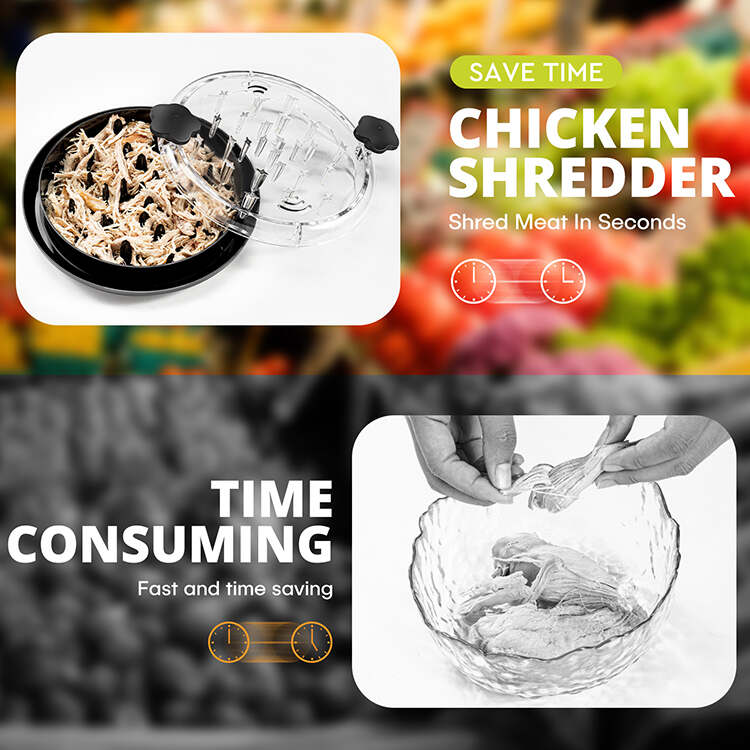

Chicken Shredder Cases

For the food processing industry, customers require the development of a manual chicken shredder. The materials must meet the following specifications High strength Food-grade compliance Stable operation.The components need precision machining to ensure smooth functionality of the shredder while maintaining safety and efficiency.

Project Overview & Solution

A client in the food processing industry needed custom machined parts for a commercial chicken shredder. The requirement was for high-strength components capable of withstanding heavy-duty use in high-temperature environments. The parts needed to be precisely machined to fit the operational needs of the shredder while maintaining safety and efficiency.

Customer Requirements and Challenges

Customer Requirements:

- High strength material

- Tight dimensional tolerances for parts to fit and operate seamlessly.

- Food-grade compliance

Key Challenges:

- Maintaining material strength while achieving intricate part shapes.

- Ensuring tight tolerances on multiple parts for proper assembly and operation.

- Dealing with the high wear and tear on the components during prolonged use.

MachMaster’s Solution

Our Manufacturing Approach:

- Injection Mold: MachMaster utilizes high-precision molds made of S316 material to ensure dimensional accuracy and extended mold life.

- Material: Food grade PP plastic

- Surface Treatment: SPI A2

- Quality Control: Custom fixturing and in-process inspections to strictly maintain ±0.05mm tolerances

Manufacturing Details

MachMaster delivered high-precision Injection Molding for chicken shredder parts, using Food grade PP plastic for strength and durability. We ensured tight tolerances, surface finishing, and fast turnaround, meeting the client’s stringent quality requirements.

| Item | Details |

|---|---|

| Material | Food grade PP plastic |

| Process | Plastic Injection Molding |

| Surface Finish | SPI A2 |

| Tolerance | ±0.01mm |

| Quantity | 2000 pcs |

| Lead Time | 25 Working Days |

| Application | Chicken Shredder Tool |

Manage Your Machining Needs with MachMaster

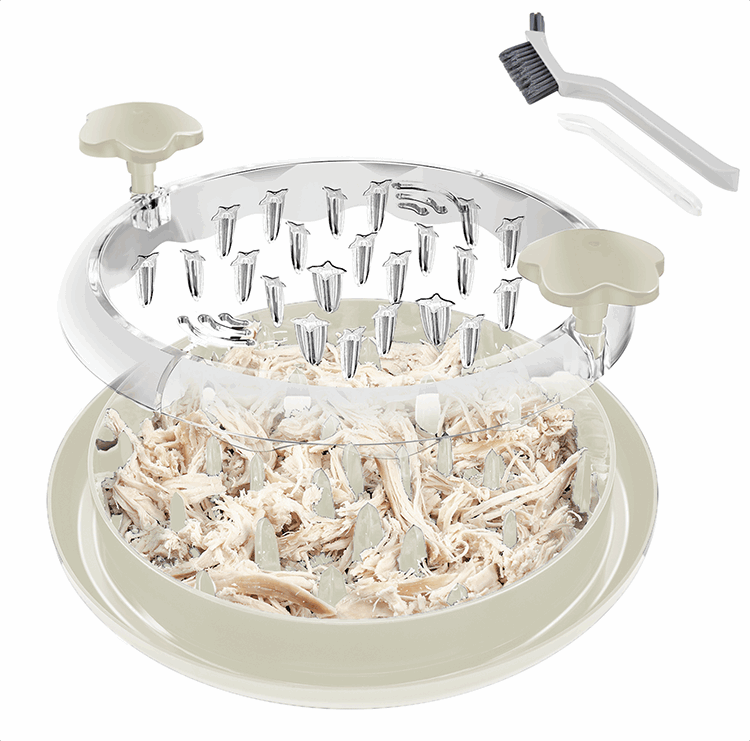

Finished Product Showcase

Injection Molding pp parts for a Chicken Shredder Tool, polished to a smooth finish for easy cleaning and long-term durability.

Our Process from File to Finished Part

01 Upload CAD File

Submit CAD drawings and RFQs with part specs and application details to get fast engineering support.

02 Review & Quote

Receive pricing and DFM feedback to ensure your design is ready for manufacturing.

03 Start Production

We begin machining or molding with selected materials and strict quality standards.

04 Parts Delivered

Parts are carefully inspected, securely packed, and shipped on time—ready for your next stage.

Capabilities That Set Us Apart

Precision, efficiency, and reliability—these are the qualities that define how we work and what our customers value most.

High Precision

Achieve tight tolerances down to ±0.01mm for demanding parts and applications.

Fast Production

Short lead times for prototypes and large orders, with consistent quality throughout.

Material Flexibility

Compatible with metals and plastics, from simple shapes to complex parts.

Engineering Support

Get design-for-manufacturing advice and full technical guidance throughout your project.

Quality Control

Every part is inspected to meet strict standards and ensure consistent performance.

Manufacturing Experience

Over two decades of hands-on production across industries and part complexities.

Our Chicken Shredder Production Shop

Proper Maintenance for Chicken Shredder

Overview:

Ensuring the cleanliness and proper maintenance of your chicken shredder tool is crucial for its longevity, safety, and efficiency. Below are the recommended steps for cleaning and maintaining the tool after each use to ensure consistent performance.

Preliminary Cleaning:

Rinse with Warm Water:

Start by rinsing the shredder tool with warm water to remove any food particles.Disassemble Removable Parts:

If the tool has removable parts like blades or stirring rods, remove them for separate cleaning.

Deep Cleaning:

Use a plastic-friendly detergent and soft sponge or brush to scrub all areas, especially those that are harder to reach or prone to buildup.

For tough stains, apply hot water or a specialized degreasing cleaner for deeper cleaning.

Disinfection Treatment:

To maintain food safety, disinfect the shredder tool using food-grade disinfectants, such as diluted bleach or other safe disinfectants, following the manufacturer’s instructions.

Natural Methods: You can also soak the tool in a solution of lemon and salt, which has natural antibacterial and deodorizing properties.

Drying and Storage:

After cleaning and disinfecting, ensure the tool is completely dry to prevent bacterial growth.

Place it in a well-ventilated area to dry naturally, or wipe it with a clean cloth.

When storing, avoid direct sunlight to prevent material degradation and ensure longevity.

Tell Us What You Need

At MachMaster, our engineers review every request and respond with tailored solutions.

Your files are kept strictly confidential and will only be used for quoting and manufacturing purposes.

- info@machcncmaster.com

- +86 139 5006 6486