Plastic Injection Molding Services

Efficient Plastic Molding from China

At MachMaster, we offer end-to-end plastic injection molding services for everything from design validation to mass production. With decades of experience and in-house tooling capabilities, we help bring complex plastic parts to life—faster, more accurately, and at scale. Whether you need transparent enclosures, overmolded grips, or industrial-grade housings, our processes are optimized for consistent results across thermoplastics and elastomers.

Manage Your Machining Needs with MachMaster

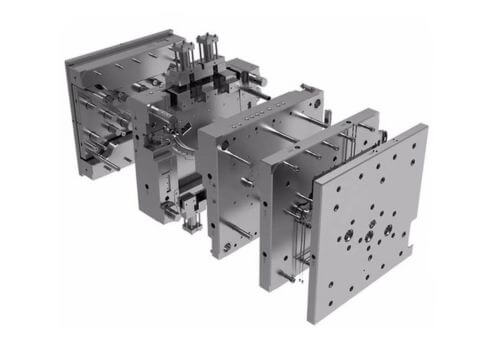

Types of Injection Molds

We support a wide range of part geometries, volumes, and design complexities—offering flexible molding solutions to match your material, performance, and production needs.

Single Cavity Mold

Used for lower-volume production or prototyping where speed, cost control, and design validation are priorities.

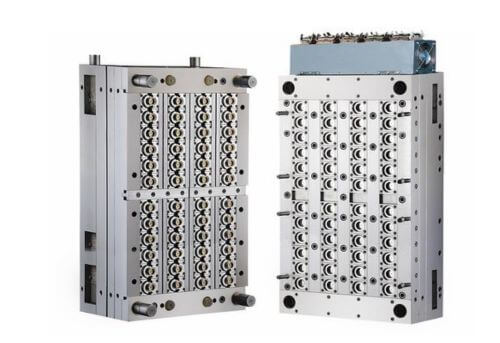

Multi Cavity Mold

Produces multiple identical parts in each cycle, reducing per-unit cost and increasing overall throughput for medium to high volumes.

Family Mold

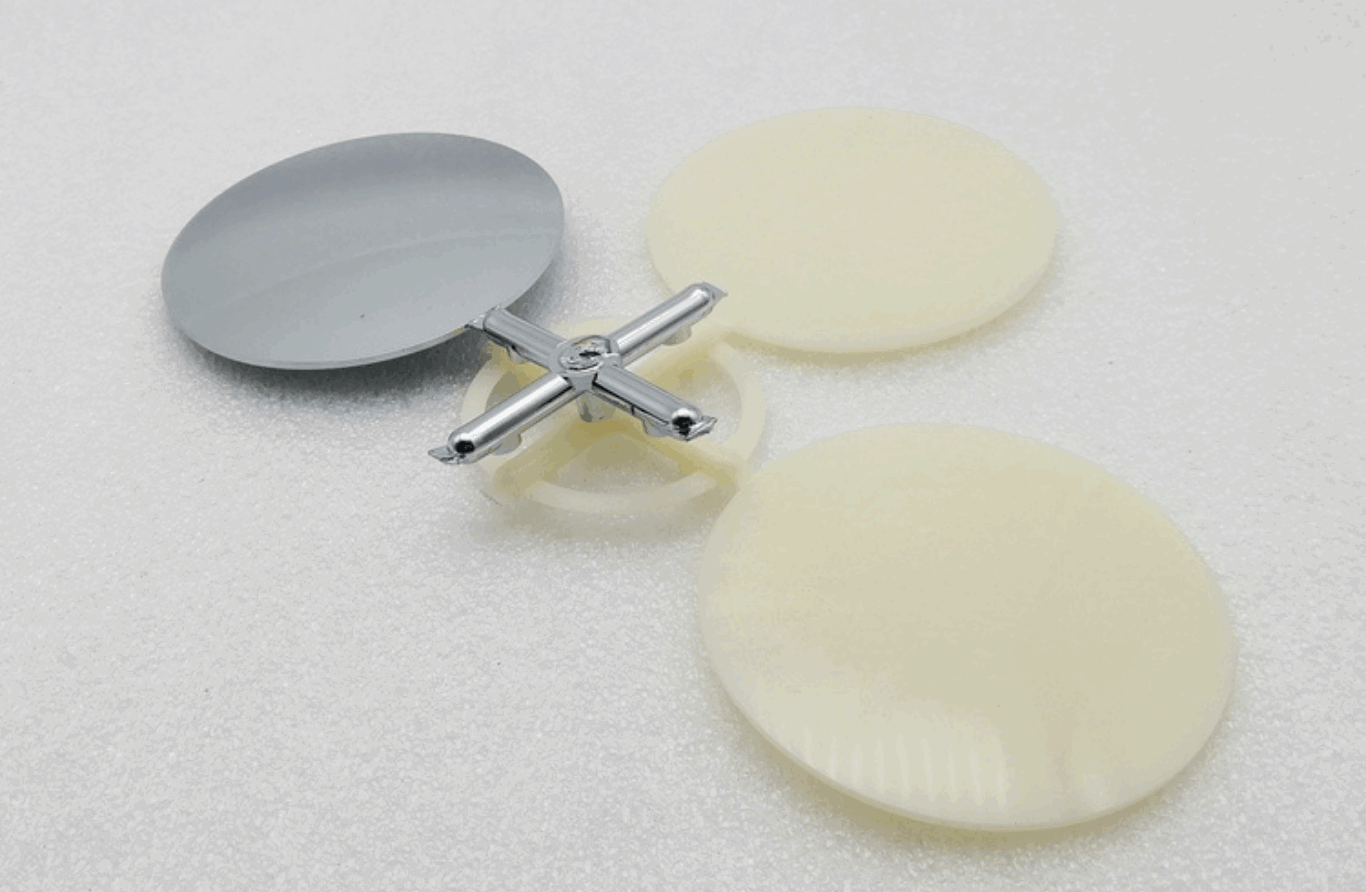

Allows different part geometries to be molded in a single cycle—ideal for assemblies or parts sets with shared material requirements.

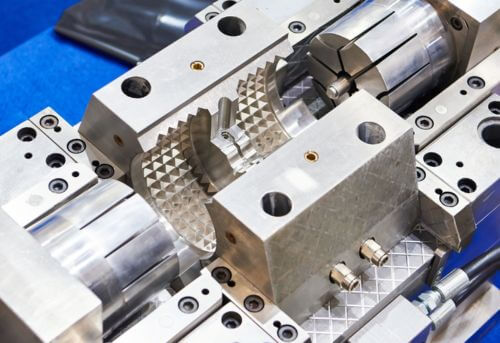

Insert Molding

Combines molded plastic with preformed components such as metal pins, threads, or bushings—enhancing part strength and functionality.

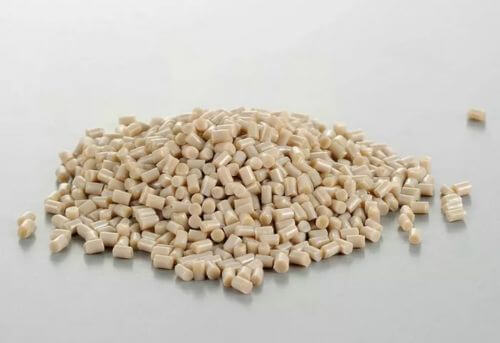

Materials for Injection Mold Tooling

Choose the right mold material to balance durability, cost, and production volume.

Cost-effective and easy to mold, materials like ABS, PP, and PS are commonly used in enclosures, housings, and consumer products.

Materials such as PC, PA, POM, and PBT provide high strength, heat resistance, and dimensional stability for functional parts.

PC, PMMA, and PETG offer clarity and optical-grade surface quality—ideal for lenses, windows, and cosmetic components.

TPU and TPE are elastomeric materials used for overmolding, seals, and grip-enhanced parts requiring flexibility and durability.

For demanding environments, we support materials like PEEK, PPS, and reinforced nylon—excellent for high-temp and chemical resistance.

Surface Finishing Options for Injection Molded Plastics

Injection molded plastic parts can be enhanced with post-processing techniques or molded-in textures. These finishes improve product aesthetics, usability, and brand presentation.

Silk Screen Printing

Silk screen printing is widely used to apply logos, icons, or instructional text onto molded plastic parts. It supports multiple colors and curved surfaces, offering excellent adhesion and durability.

✔ Suitable for brand logos, labels, and patterns

✔ High clarity, abrasion-resistant prints

✔ Common in consumer electronics, packaging, and appliances

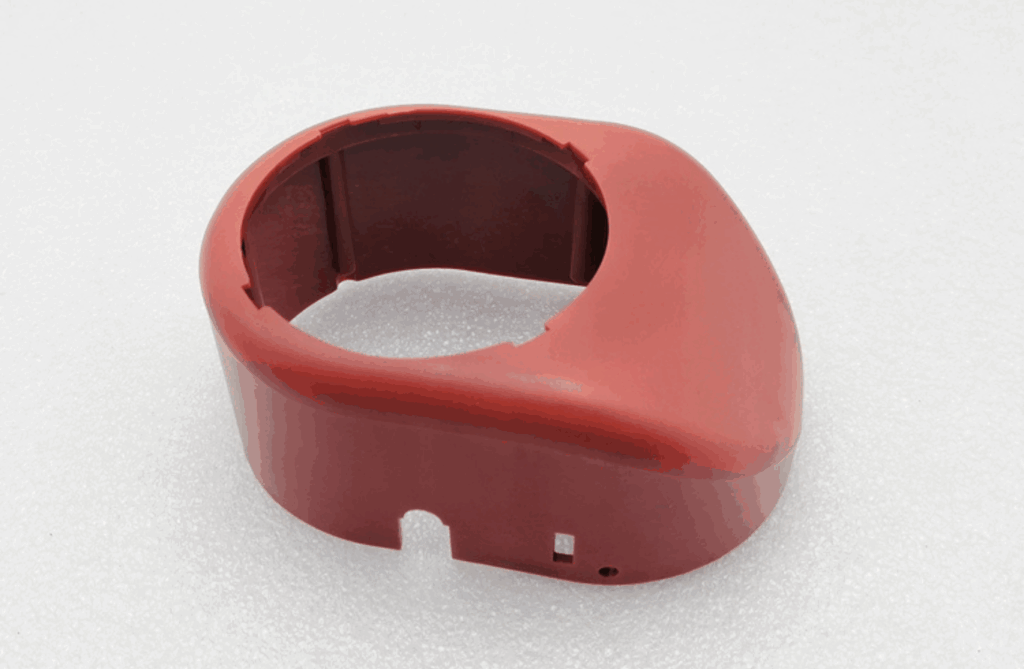

Spray Painting / Coating

Spray coating enhances both the appearance and protective properties of plastic parts. It allows for a variety of finishes, including matte, glossy, soft-touch, and metallic effects.

✔ Applied post-molding under dust-controlled conditions

✔ Custom color matching with RAL/Pantone support

✔ Ideal for cosmetic packaging, automotive trim, and home goods

Electroplating

Plastic electroplating adds a metallic finish to plastic parts while improving surface hardness and visual appeal. Vacuum plating is preferred for uniform and eco-friendly results.

✔ Chrome, nickel, or custom finishes available

✔ Requires base coating + activation process

✔ Used in automotive interiors, household appliances, and luxury packaging

SPI Mold Finish

The final surface texture of a molded part is often defined by the SPI (Society of the Plastics Industry) mold finish. This determines gloss level directly from the mold—no post-processing needed.

✔ SPI A1–A3: mirror gloss (polished)

✔ SPI B1–B3: semi-gloss (paper polish)

✔ SPI C1–C3: matte (stone finish)

✔ SPI D: textured/rough (dry blast)

✔ Eliminates need for secondary finish in many applications

Why MachMaster Is the Right Choice

We combine engineering precision with production flexibility—offering tight tolerances, diverse materials, and fast lead times to meet your manufacturing needs. Whether you require prototypes or complex end-use parts, MachMaster delivers consistent quality and performance.

Tight Tolerance Accuracy

Parts machined to ±0.01 mm for functional fit, surface finish, and critical dimensions.

Low-Volume Friendly

From one-off prototypes to short runs—no MOQ, fast response, flexible output.

Precision for Complex Parts

Equipped with 60+ CNC machines for multi-surface and complex contour machining.

Material Versatility

Supports aluminum, stainless steel, brass, POM, PC, and other engineering plastics.

ISO 9001 Certified Workflow

Triple-stage inspection ensures every part meets your spec before shipment.

Rapid Lead Times

Prototypes delivered in as fast as 1 day, with full tracking and schedule control.

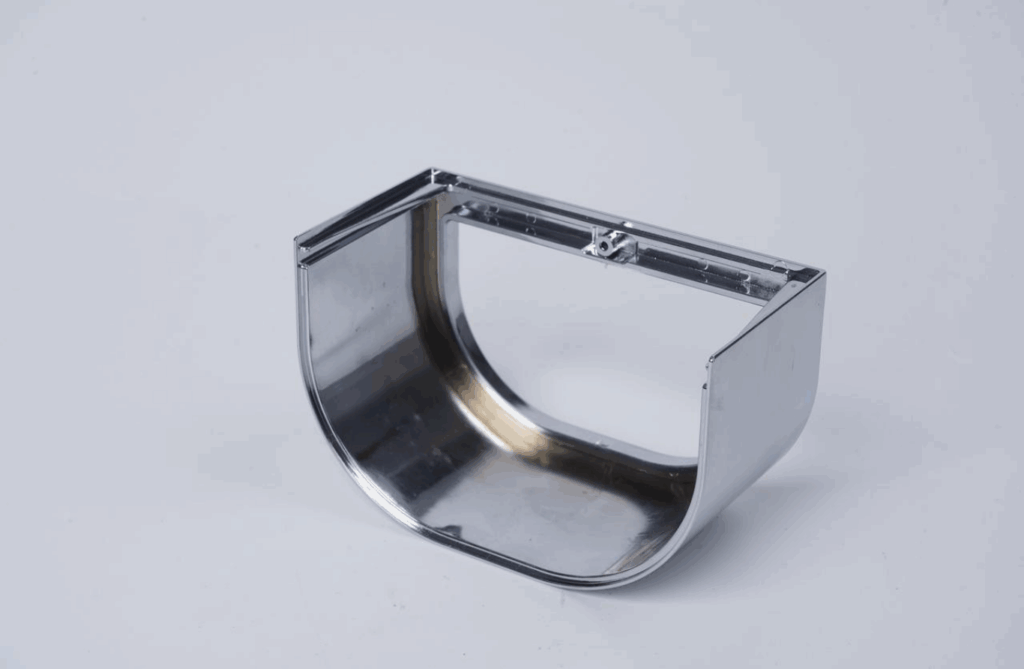

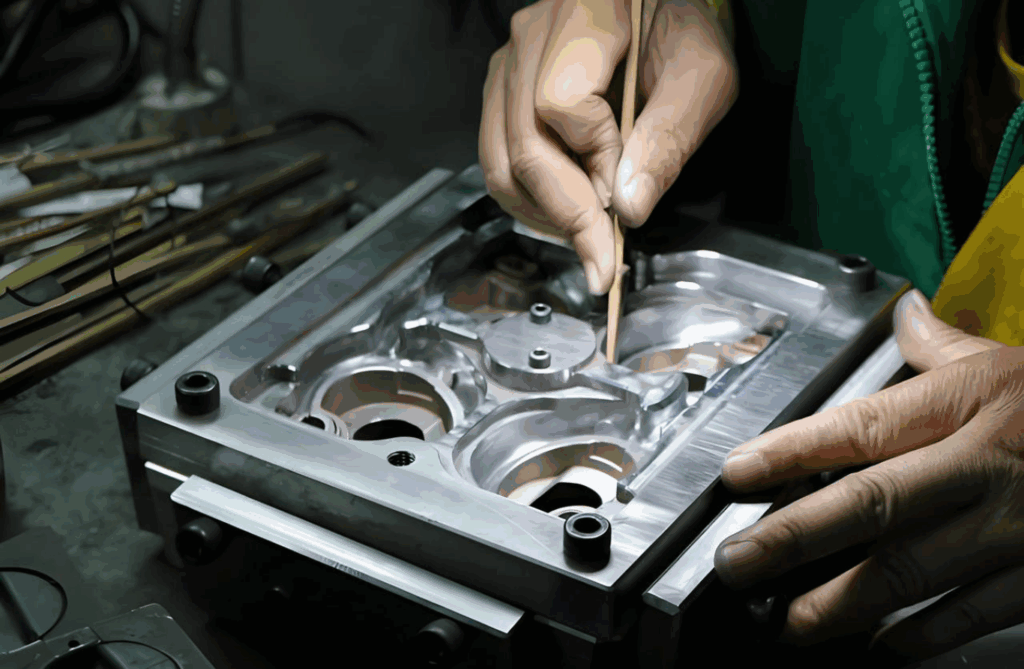

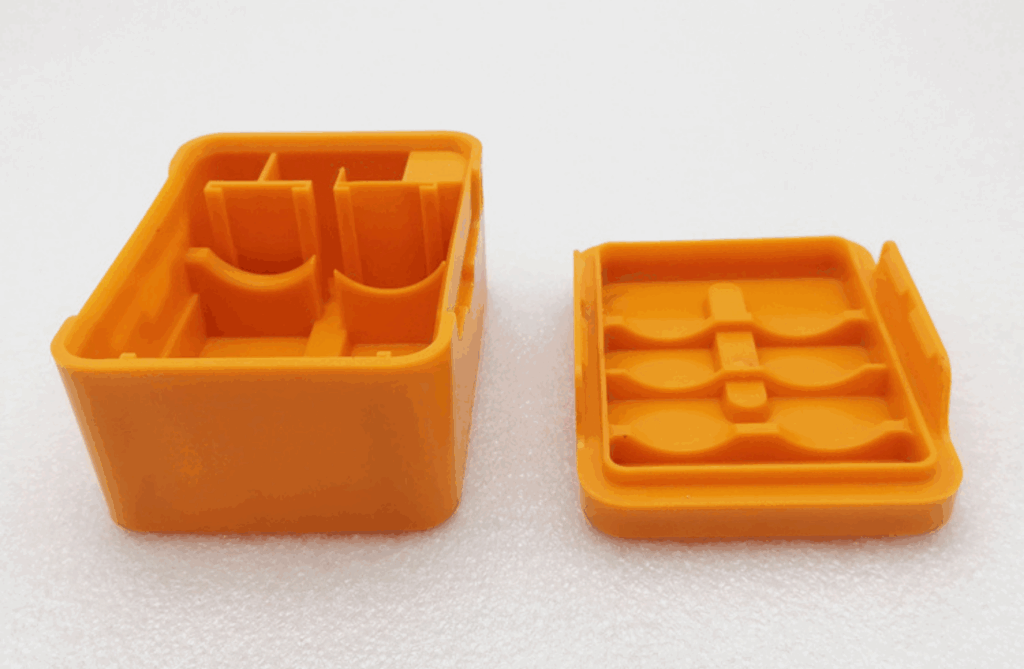

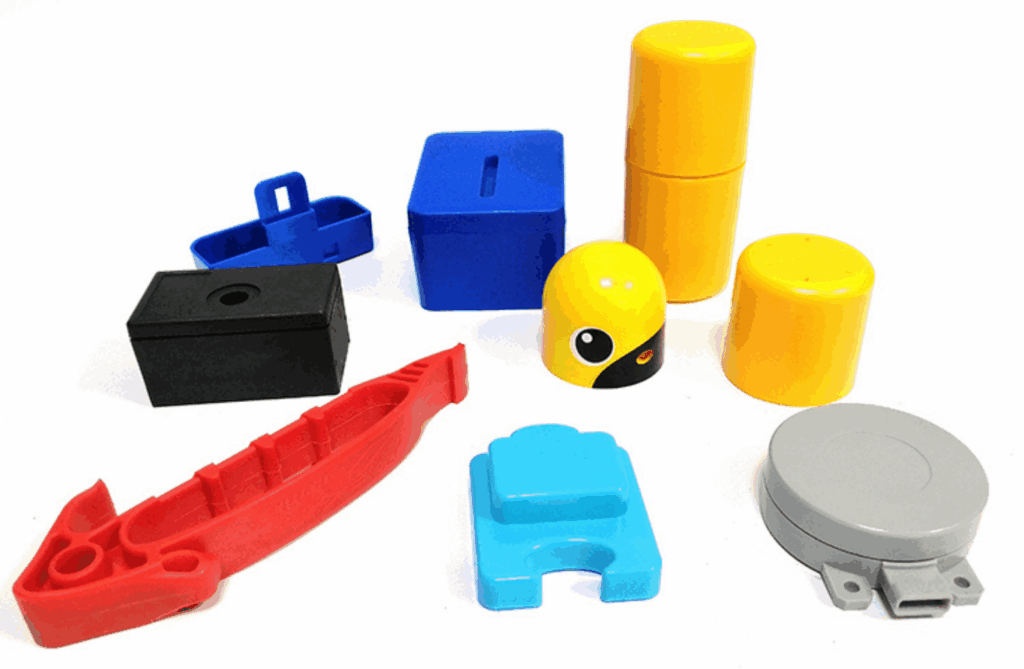

Real-World Plastic Injection Molding Samples

Browse real samples of custom-molded plastic parts we’ve delivered for aerospace, medical, consumer electronics, industrial automation, and other precision-critical sectors. Each part reflects our ability to meet tight tolerances, complex geometries, and industry-specific standards.

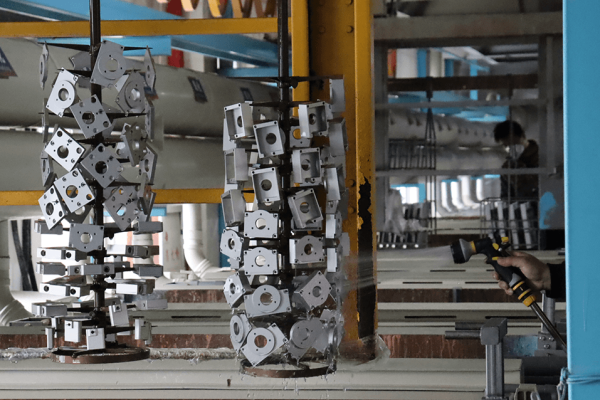

Speed Meets Precision at MachMaster

See our team, process, and precision in action at Xiamen MachMaster Co., Ltd—where every part is backed by expertise, systems, and measurable results.

FAQs About Plastic Injection Molding

What Is Plastic Injection Molding?

Plastic injection molding is a manufacturing process that involves injecting molten plastic into a steel or aluminum mold to form parts with complex shapes and tight tolerances. It’s ideal for producing high volumes of identical components with excellent repeatability.

What Types Of Plastic Materials Are Available?

Common materials include ABS, PC, PP, POM, PA (Nylon), PE, PET, PS, and more. Each material offers different benefits such as heat resistance, flexibility, chemical resistance, or mechanical strength.

How Long Does The Injection Molding Process Take?

Once the mold is ready, injection molding cycles are very short—typically a few seconds to a couple of minutes per part. Mold fabrication time varies based on complexity and ranges from a few days to several weeks.

What Tolerances Can Be Achieved With Plastic Injection Molding?

Standard tolerances are ±0.1 mm, but tighter tolerances are possible with proper mold design, material selection, and processing controls.

Explore More of Our Resources

Fundamentals & Design:

- Smart Steps in Plastic Mold Design

- 10 Types of Injection Molding Molds

- Quick Guide to Plastic Injection Molding Tolerances

Materials & Prototypes:

- Top 8 Materials for Plastic Injection Molding

- What Plastic Is Used for Injection Molding?

- A Quick Guide to Prototype Plastic Injection Molding

- Plastic Prototype Manufacturing: What You Need to Know

Industry & Applications:

- Top 7 Plastic Injection Molding Companies

- Top 9 Plastic Injection Molding Manufacturers in China

- How Automotive Plastic Injection Molding Works

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.

Tell Us What You Need

At MachMaster, our engineers review every request and respond with tailored solutions.

Your files are kept strictly confidential and will only be used for quoting and manufacturing purposes.

- info@machcncmaster.com

- +86 139 5006 6486