Injection Molding Tooling Solutions

Precision Tooling Solutions for Injection Molding

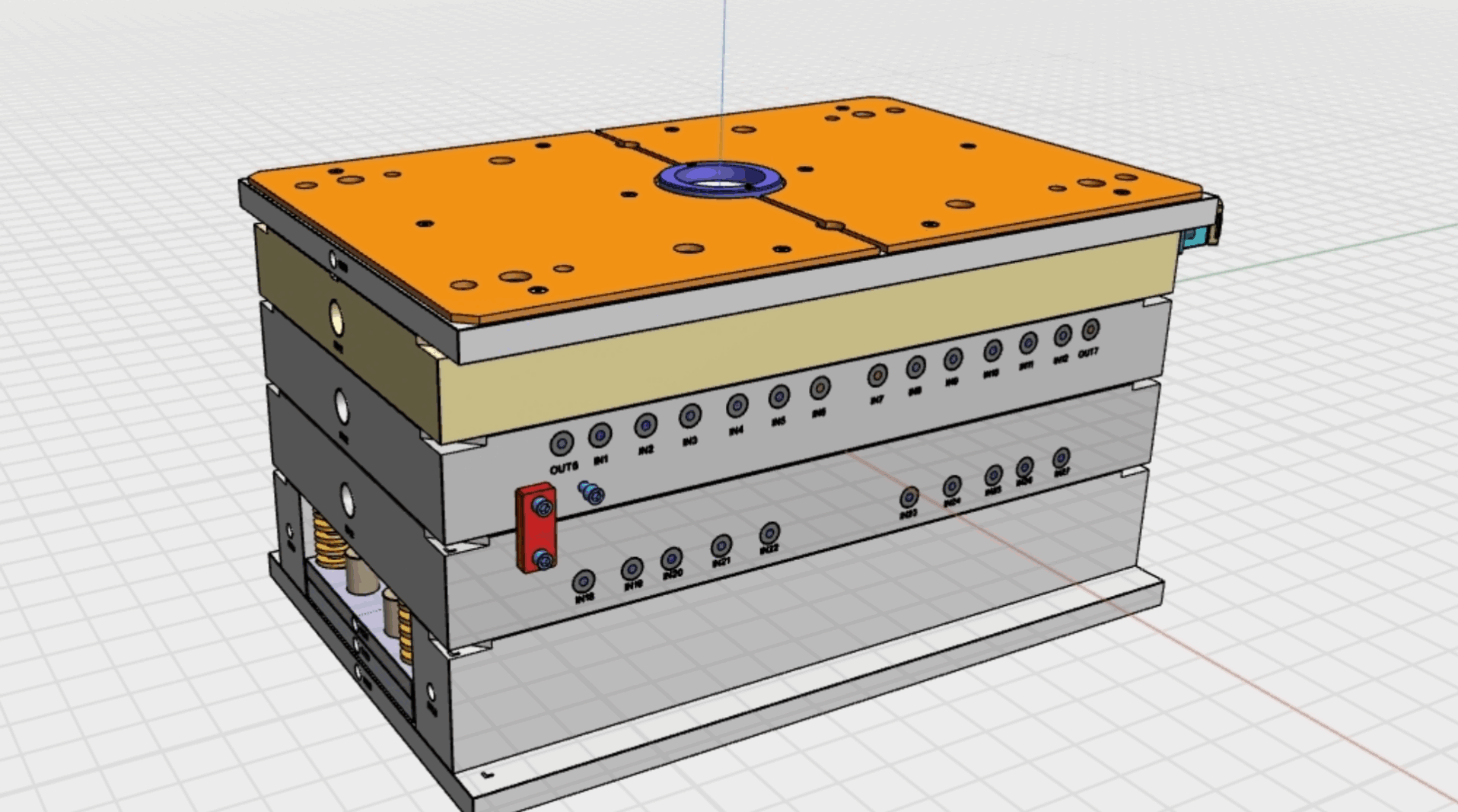

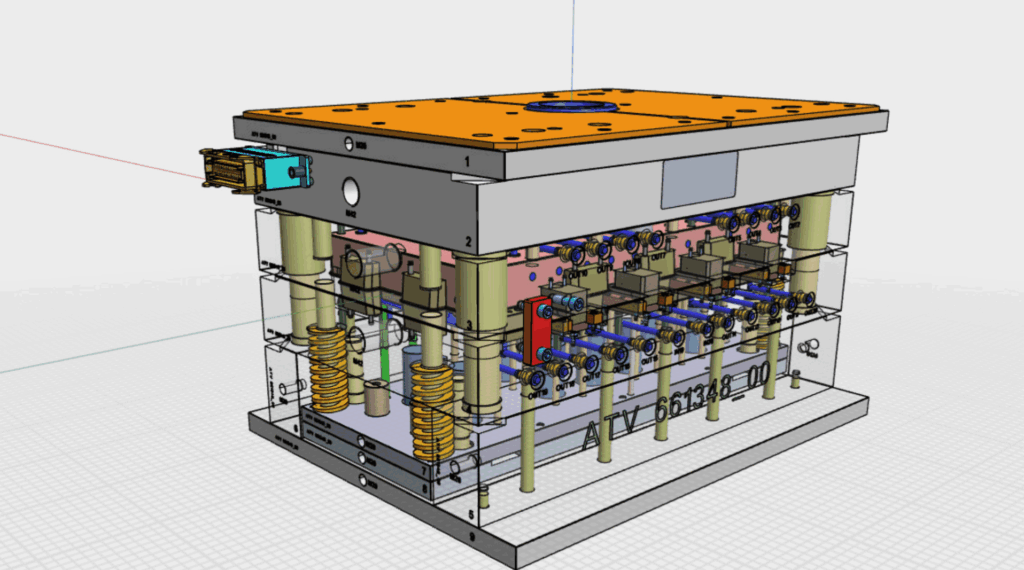

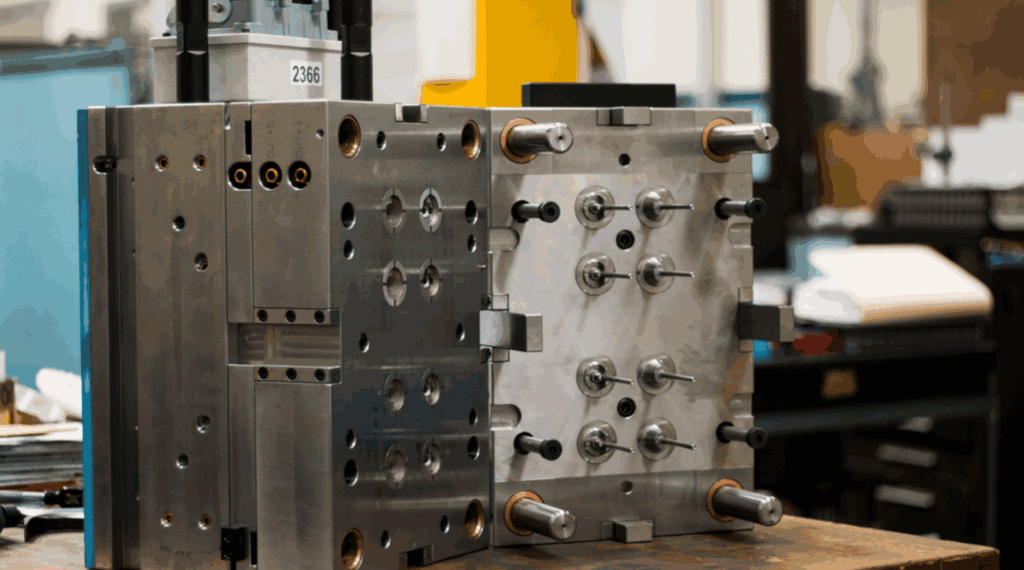

Our in-house tooling services deliver durable, high-precision molds—engineered for complex geometries, rapid cycles, and consistent performance. With CNC, EDM, and surface finishing capabilities, we build molds that meet demanding tolerances from prototype to production.

MachMaster specializes in building high-quality injection molds tailored for rapid prototyping and volume production. From DFM support to mold flow analysis, we help optimize part design and tooling feasibility.

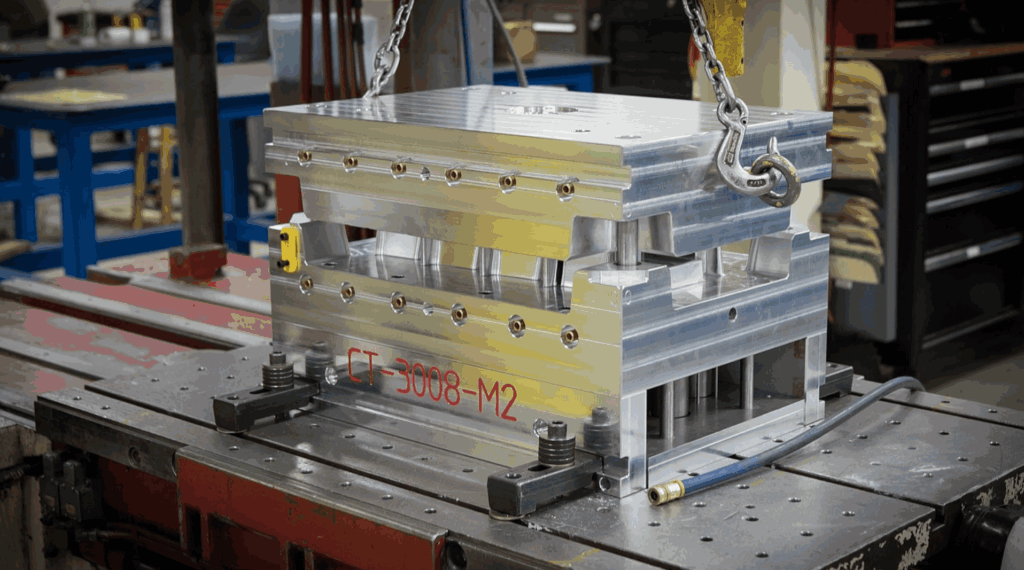

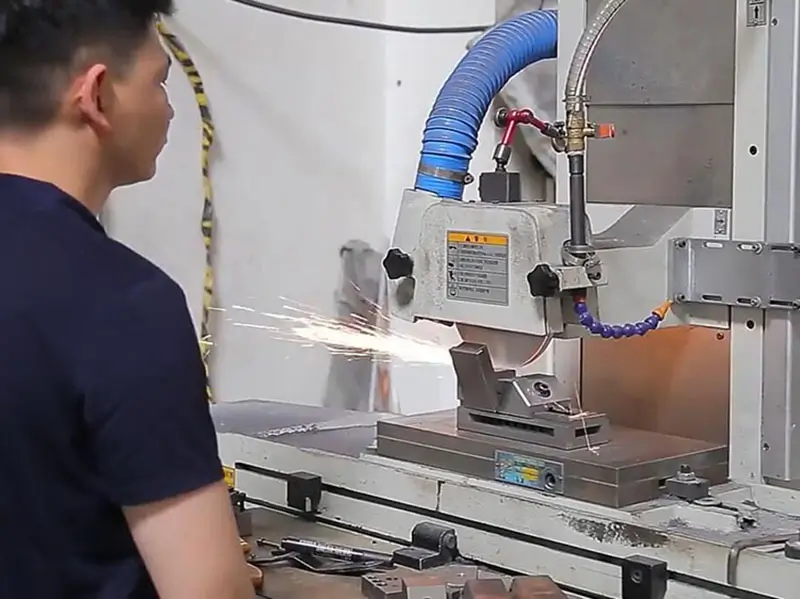

Our in-house mold shop features advanced CNC machining centers, EDM equipment, and high-speed surface grinders. This enables us to produce both aluminum and hardened steel molds with tight tolerances and fast lead times.

Whether you need prototype molds, bridge tooling, or high-volume multi-cavity production tools, our ISO 9001:2015 certified team ensures every mold is built for longevity, precision, and repeatable output.

Manage Your Machining Needs with MachMaster

Types of Injection Molds

Explore our injection mold tooling options tailored for diverse applications—from rapid prototyping to high-volume production. At MachMaster, we design precision-engineered molds to meet your part quality, speed, and cost requirements.

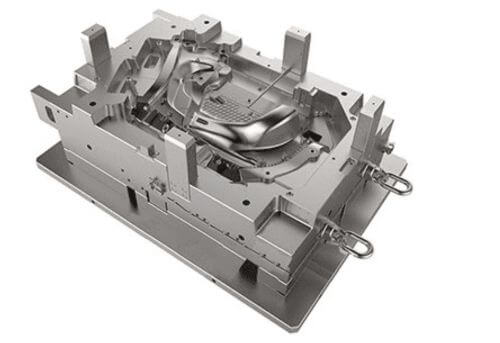

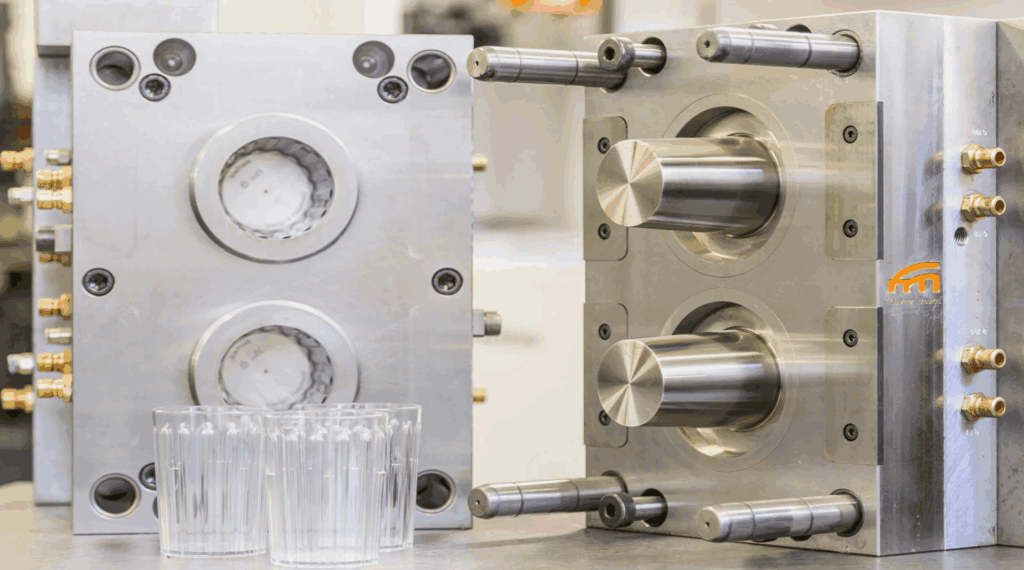

Single Cavity Mold

Ideal for low-volume production and prototype validation, our single cavity molds provide consistent quality and tight control over part dimensions—great for cost-conscious custom projects.

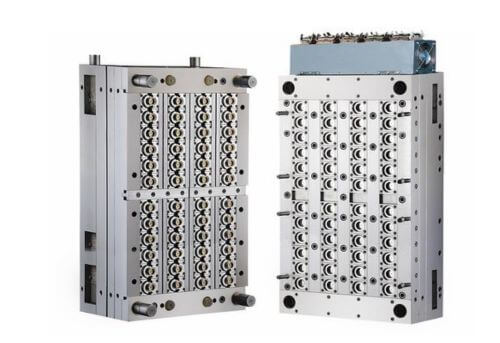

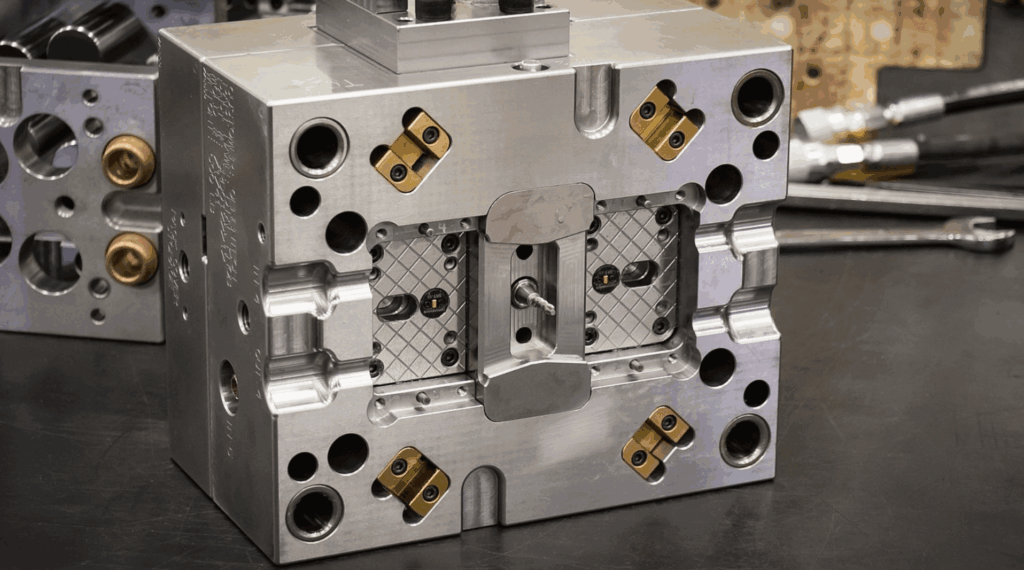

Multi Cavity Mold

Designed for higher throughput, multi cavity molds allow simultaneous production of multiple parts per cycle, significantly improving productivity and reducing unit costs.

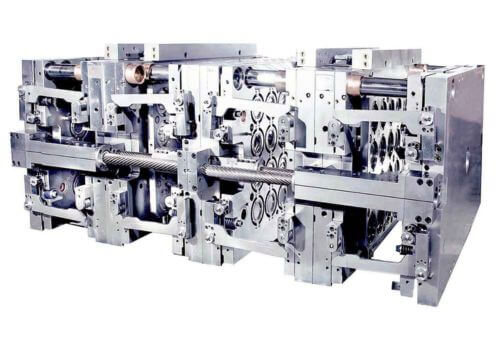

Stack Mold

Stack molds double the output by utilizing multiple parting lines in a single mold base. Perfect for high-volume runs, they minimize cycle time without sacrificing precision.

2K Injection Mold

Our 2K molds support dual-material injection, enabling efficient production of parts with both hard and soft components—ideal for ergonomic, functional, or aesthetic integration.

Materials for Injection Mold Tooling

Choose the right mold material to balance durability, cost, and production volume.

Tool steel is the most widely used material for injection molds due to its excellent hardness, wear resistance, and machinability. Ideal for both prototype and production tooling, it provides the precision needed for high-tolerance parts.

Common Grades: P20, H13, S7, NAK80, S136, S136H, 718, 718H, 738

Stainless steel offers superior corrosion resistance and extended mold life. It’s best suited for high-volume production and parts requiring fine surface finishes or contact with corrosive materials.

Common Grades: 420, NAK80, S136, 316L, 316, 301, 303, 304

Aluminum molds are lightweight and cost-efficient, offering excellent heat dissipation for faster cycle times. Ideal for short-run production and rapid prototyping, they reduce tooling lead time and investment.

Common Grades: 6061, 5052, 7075

Custom Mold Solutions for Every Stage

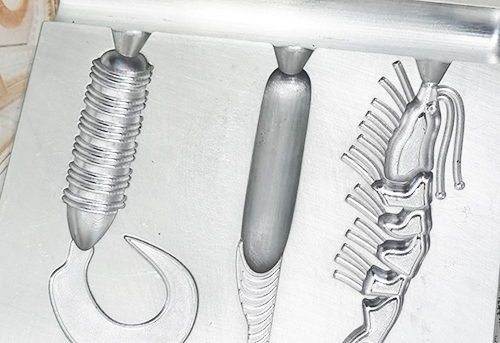

Rapid Tooling for Prototyping

Accelerate your product development with fast-turnaround aluminum tooling. Ideal for quick design verification and short-run production, our rapid molds help you move from prototype to part in days—not weeks.

Durable Steel Molds for Mass Production

Engineered for high-volume cycles, our hardened steel molds deliver reliable, repeatable performance. Tailored to your specs, they ensure smooth and stable part production.

Why MachMaster Is the Right Choice

We combine engineering precision with production flexibility—offering tight tolerances, diverse materials, and fast lead times to meet your manufacturing needs. Whether you require prototypes or complex end-use parts, MachMaster delivers consistent quality and performance.

Tight Tolerance Accuracy

Parts machined to ±0.01 mm for functional fit, surface finish, and critical dimensions.

Low-Volume Friendly

From one-off prototypes to short runs—no MOQ, fast response, flexible output.

Precision for Complex Parts

Equipped with 60+ CNC machines for multi-surface and complex contour machining.

Material Versatility

Supports aluminum, stainless steel, brass, POM, PC, and other engineering plastics.

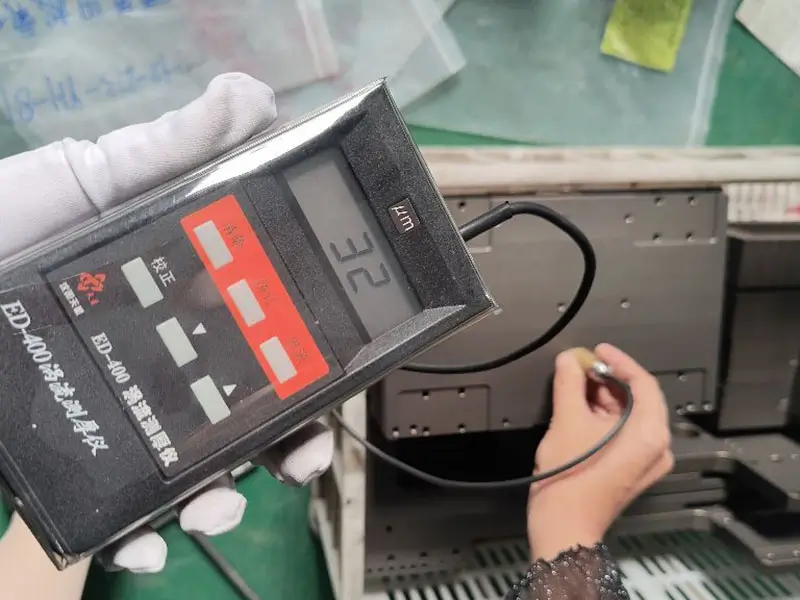

ISO 9001 Certified Workflow

Triple-stage inspection ensures every part meets your spec before shipment.

Rapid Lead Times

Prototypes delivered in as fast as 1 day, with full tracking and schedule control.

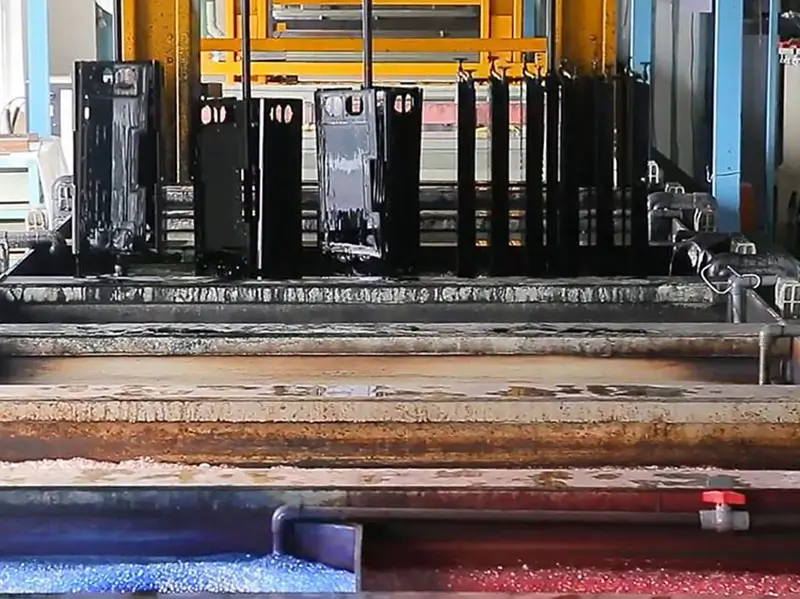

Real-World Injection Mold Tooling Samples

Explore real injection mold tooling samples we’ve made for medical, electronics, and industrial applications.

Speed Meets Precision at MachMaster

See our team, process, and precision in action at Xiamen MachMaster Co., Ltd—where every part is backed by expertise, systems, and measurable results.

Injection Mold Tooling FAQs

What Is Injection Mold Tooling?

Injection mold tooling refers to the design and manufacture of the mold used in the injection molding process. It defines the final part shape and ensures production accuracy and repeatability.

How Long Does It Take to Make a Mold?

Lead time depends on the complexity. Prototype molds take around 3–7 days, while production molds with multi-cavities may require 2–4 weeks or more.

What Materials Are Used for Mold Tooling?

We commonly use tool steel (P20, H13, S136), stainless steel (420, NAK80, 316L), and aluminum (6061, 7075), depending on production volume and required durability.

How Much Does Mold Tooling Cost?

Costs vary based on mold complexity, material type, surface finishes, and expected tool life. Aluminum molds are budget-friendly for prototyping, while hardened steel is ideal for mass production.

Explore More of Our Resources

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.

Tell Us What You Need

At MachMaster, our engineers review every request and respond with tailored solutions.

Your files are kept strictly confidential and will only be used for quoting and manufacturing purposes.

- info@machcncmaster.com

- +86 139 5006 6486