Wire EDM Services

High-Tolerance EDM Machining from China

MachMaster offers high-precision EDM (Electrical Discharge Machining) services for both prototypes and low-volume production parts. Our EDM capabilities allow us to machine intricate geometries, sharp corners, and hardened materials with exceptional accuracy.

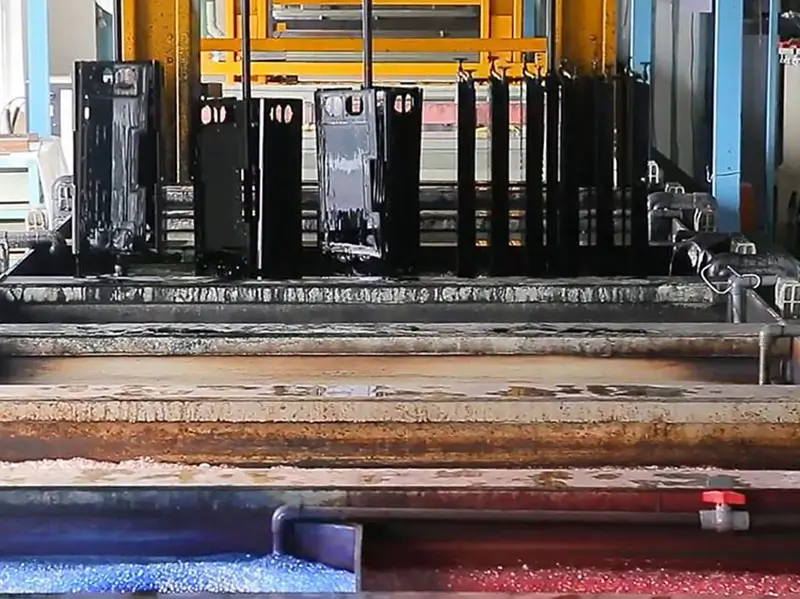

Using advanced Wire EDM and Sinker EDM equipment, we can produce components that are difficult—or impossible—to machine using traditional cutting tools. EDM is particularly effective for mold tooling, aerospace components, medical fixtures, and other high-performance parts.

With support for over 60 certified materials including stainless steel, titanium, tool steels, and conductive alloys, we ensure consistent quality across a broad range of applications.

Thanks to in-house quality control and ISO 9001:2015 certification, we deliver precision parts that meet your most demanding tolerance, surface finish, and complexity requirements.

Manage Your Machining Needs with MachMaster

Why MachMaster Is the Right Choice

We combine engineering precision with production flexibility—offering tight tolerances, diverse materials, and fast lead times to meet your manufacturing needs. Whether you require prototypes or complex end-use parts, MachMaster delivers consistent quality and performance.

Tight Tolerance Accuracy

Parts machined to ±0.01 mm for functional fit, surface finish, and critical dimensions.

Low-Volume Friendly

From one-off prototypes to short runs—no MOQ, fast response, flexible output.

Precision for Complex Parts

Equipped with 60+ CNC machines for multi-surface and complex contour machining.

Material Versatility

Supports aluminum, stainless steel, brass, POM, PC, and other engineering plastics.

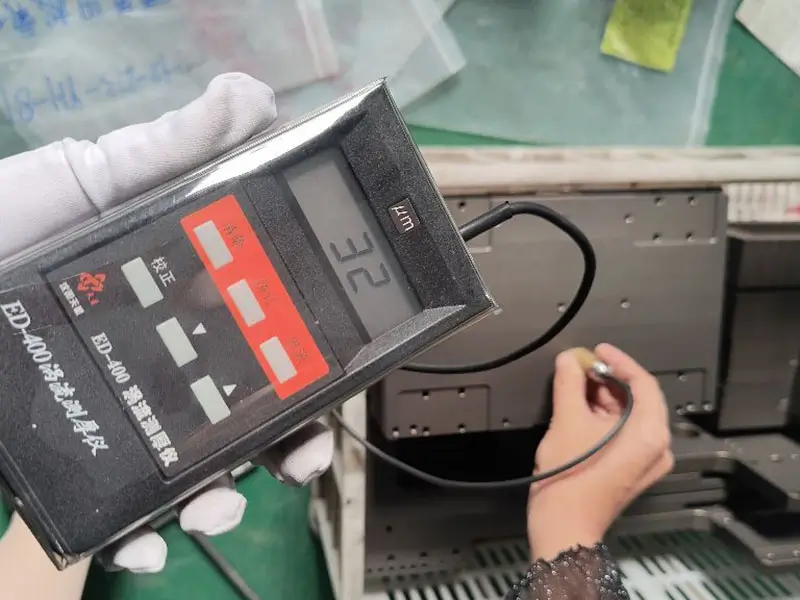

ISO 9001 Certified Workflow

Triple-stage inspection ensures every part meets your spec before shipment.

Rapid Lead Times

Prototypes delivered in as fast as 1 day, with full tracking and schedule control.

EDM Machined Part Examples

Explore real-world EDM components we’ve produced—featuring complex profiles, tight tolerances, and smooth finishes for industries.

Speed Meets Precision at MachMaster

See our team, process, and precision in action at Xiamen MachMaster Co., Ltd—where every part is backed by expertise, systems, and measurable results.

Built by Experts, Backed by Process

At MachMaster, every project is supported by a dedicated team of experts across engineering, production, quality control, logistics, quoting, and customer support. Through integrated collaboration and precise process management, we ensure consistent quality, reliable delivery, and exceptional service at every stage of your project.

Project & Quotation Team

Manages files, RFQs, and lead time tracking with 24h quoting.

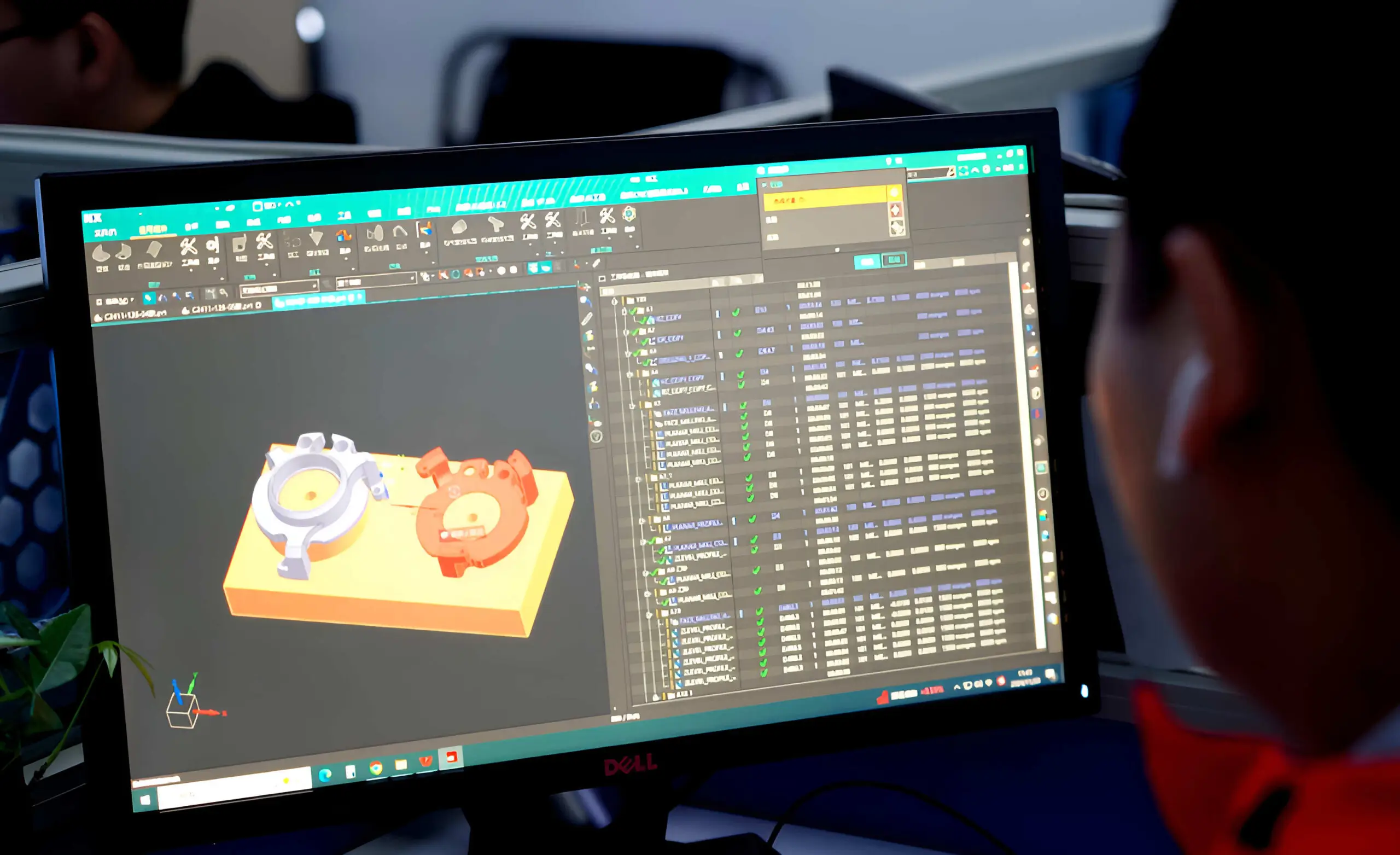

Engineering Team

Provides DFM analysis and technical solutions from design review to production readiness.

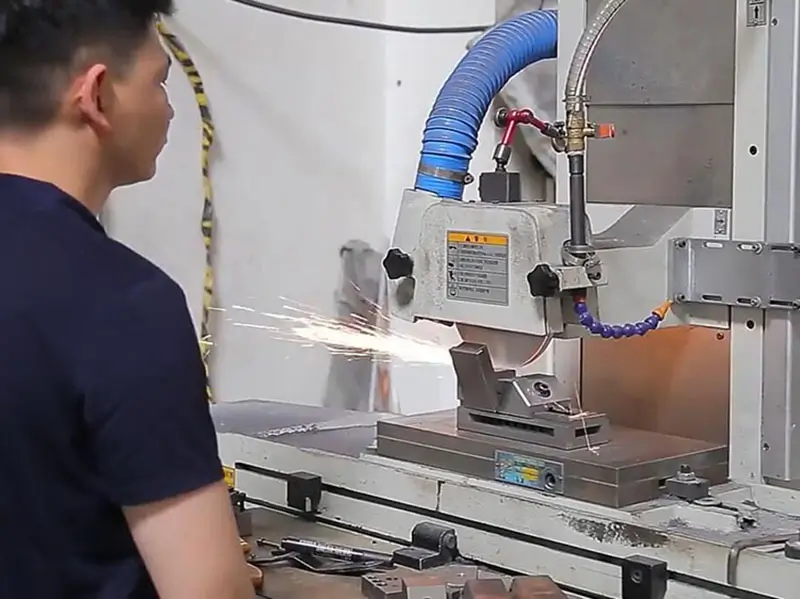

Production Team

Runs CNC, molding, casting, and finishing with precision and process control.

Quality Control Team

Handles inspection at every stage with full traceability and ISO standards.

Packaging & Logistics Team

Customizes packaging and ensures safe delivery with accurate scheduling.

Customer Support Team

Handles progress updates, feedback, and after-sales issues with fast response.

Wire EDM Overview

What Is EDM Machining?

EDM (Electrical Discharge Machining) is a manufacturing method that uses electrical sparks to erode conductive materials with extreme precision. It’s ideal for intricate cavities, hard metals, and complex geometries that traditional machining struggles to handle.

What Materials Can Be Processed With EDM?

EDM is suitable for all conductive materials, including hardened steels, titanium, tungsten, Inconel, and carbide. It’s especially effective for high-precision components made from tough or heat-treated metals.

What Are The Advantages Of EDM?

EDM offers ultra-precise results, minimal stress on parts, and the ability to create complex or deep cavities. It allows tight tolerances, smooth surface finishes, and eliminates the need for excessive clamping or mechanical force.

What Types Of EDM Are Available?

There are two main types of EDM: Wire EDM and Sinker EDM. Wire EDM uses a thin wire to cut through material, ideal for intricate profiles. Sinker EDM uses an electrode to form cavities and is often used in mold and die production.

How Accurate Is EDM Machining?

MachMaster’s EDM machines achieve tolerances as tight as ±0.005 mm, with minimal deformation—making it ideal for delicate or high-performance parts.

Explore More of Our Resources

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.

Tell Us What You Need

At MachMaster, our engineers review every request and respond with tailored solutions.

Your files are kept strictly confidential and will only be used for quoting and manufacturing purposes.

- info@machcncmaster.com

- +86 139 5006 6486