Anodizing Surface Finishing Services

Professional Anodizing Services

At MachMaster, we operate our own anodizing workshop, giving us full control over quality, lead time, and process consistency. Whether you’re seeking enhanced surface protection, color customization, or industrial-grade durability, our anodizing services cover a wide range of functional and aesthetic needs.

Type II – Standard Anodizing

The most common anodizing process, ideal for general-purpose aluminum surface treatment. Type II creates a thin oxide layer that is dye-absorbent, corrosion-resistant, and visually appealing—perfect for consumer products and decorative parts.

✔ Features: Thin film, colorable, vibrant finish

✔ Applications: Consumer electronics, aluminum accessories, homeware parts

Type III – Hard Anodizing

Designed for parts requiring extreme durability, abrasion resistance, and insulation. Type III anodizing produces a much thicker and denser oxide layer under controlled conditions, making it ideal for industrial and mechanical components.

✔ Features: Thick film (up to 100µm), high hardness (HV300+), superior corrosion and wear resistance

✔ Applications: Aerospace parts, pneumatic fittings, mechanical housings

Alodine

While retaining certain properties of the anodic oxide film (such as wear and corrosion resistance), it endows or maintains a certain degree of electrical conductivity on the surface.

✔ Features: Thin, Protective, Conductive, Passive (meaning it doesn’t easily react with other materials)

✔ Applications: Aerospace, Electronics, Industrial hardware,Defense and telecom

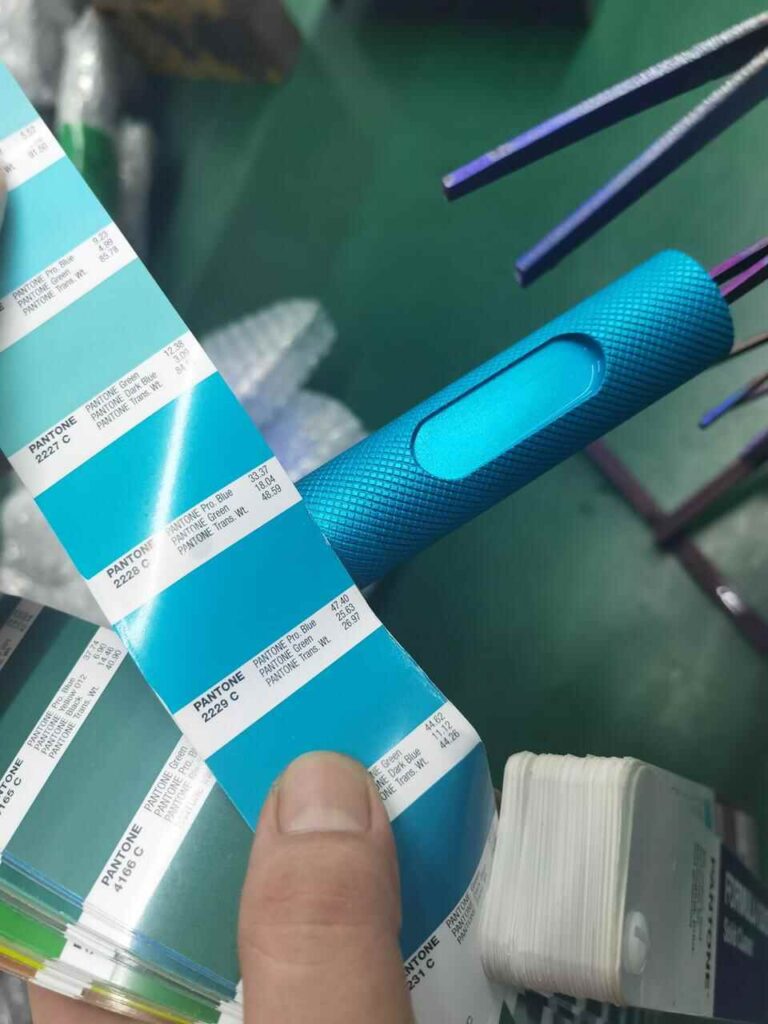

Custom Color – RAL / Pantone

We offer custom color anodizing to match your brand identity or design intent—select any RAL or Pantone color standard. This option is popular for high-end product design that emphasizes visual appeal and brand consistency.

✔ Features: Full color customization, excellent uniformity, professional finish

✔ Applications: Branding parts, consumer goods, promotional products

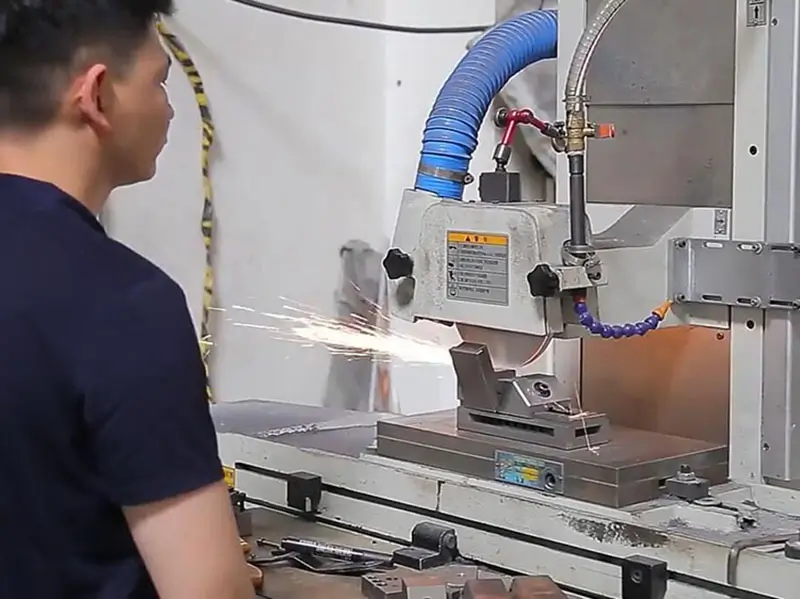

Manage Your Machining Needs with MachMaster

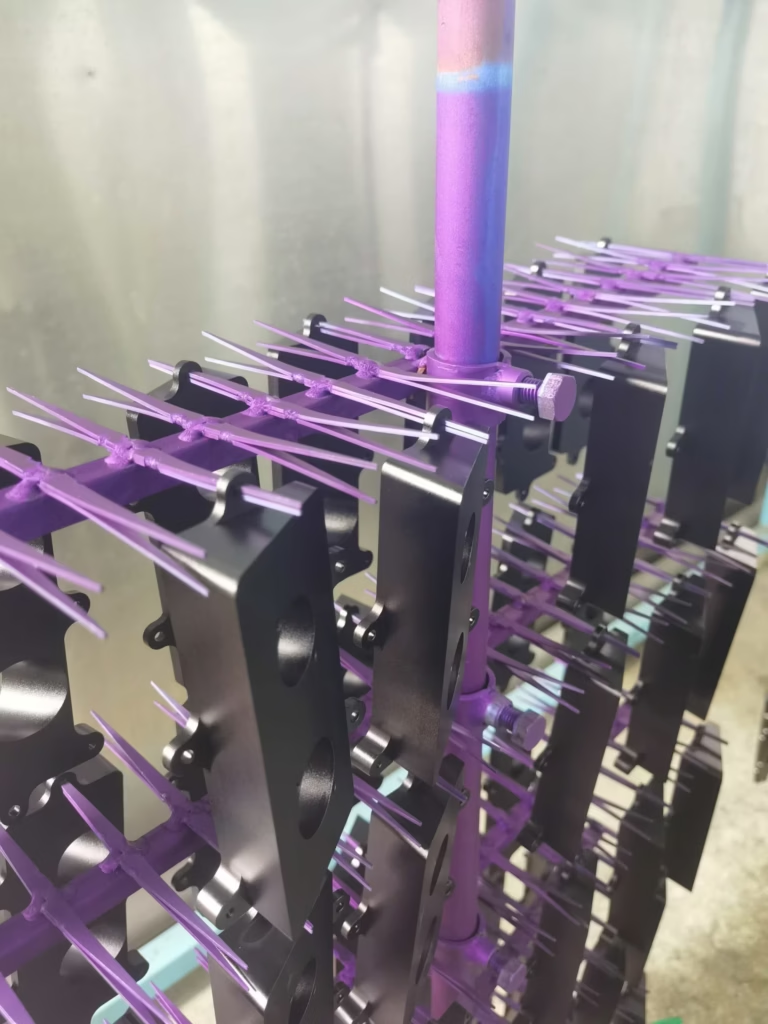

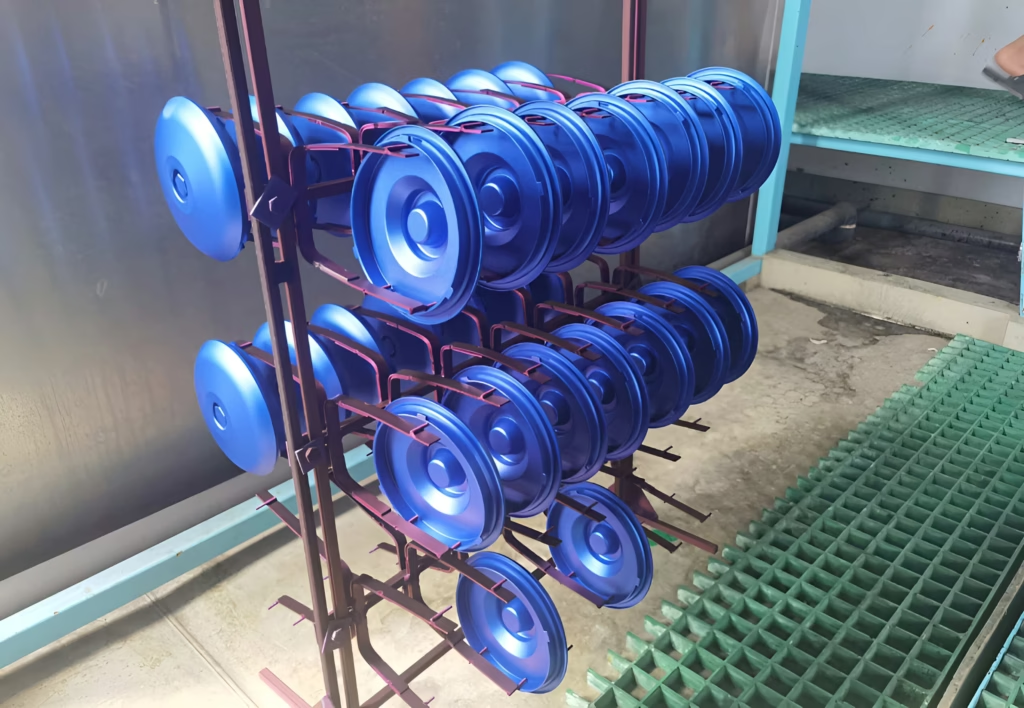

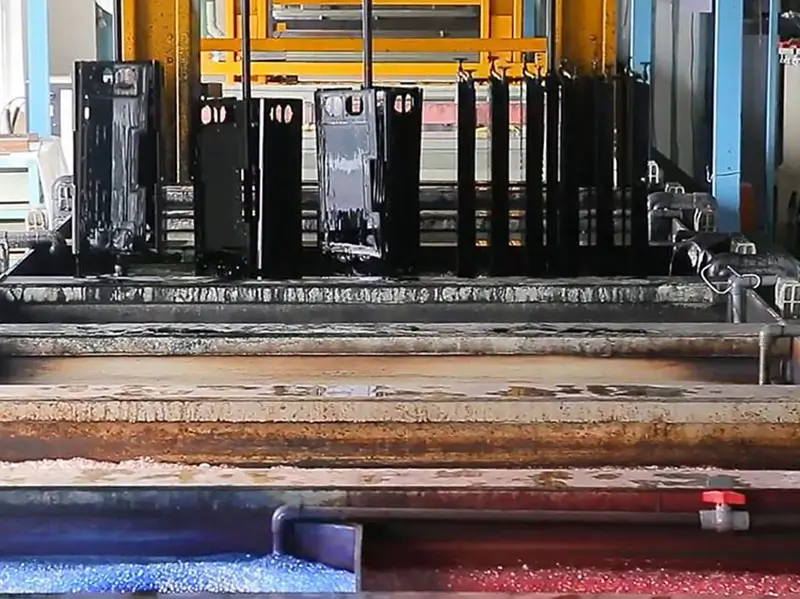

Anodizing Workshop & Production Line

Our state-of-the-art anodizing facility is designed to handle both small-batch and high-volume aluminum parts with consistent quality and fast turnaround. Equipped with advanced automated control systems and electrochemical tanks, we ensure precise oxidation thickness, color uniformity, and surface durability.

From pretreatment to sealing, each stage is closely monitored to meet industry standards for corrosion resistance, wear protection, and cosmetic appeal. Whether you need clear, black, red, blue, or custom dyed finishes, our plant supports grits ranging from 80# to 180# to achieve the desired texture.

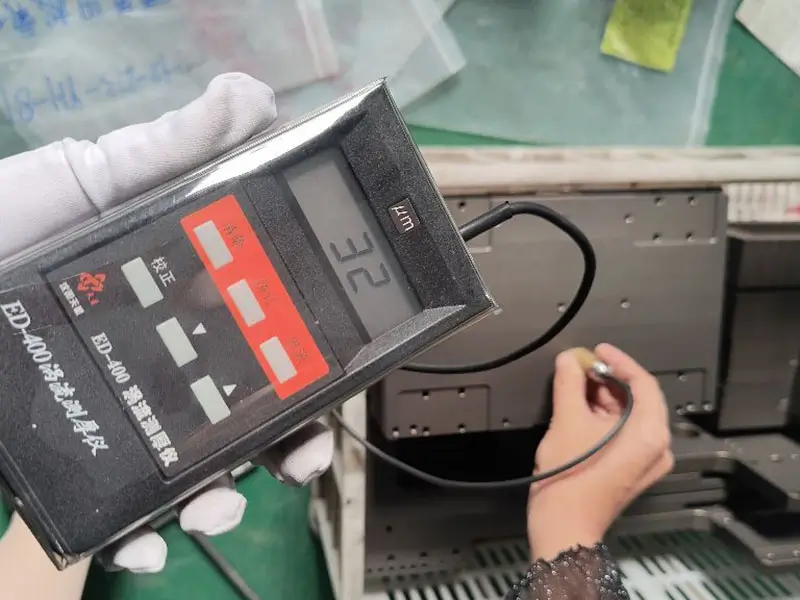

With ISO 9001:2015 certified quality control and a dedicated anodizing team, MachMaster delivers high-performance surface finishes trusted by clients in automotive, aerospace, electronics, and industrial equipment industries.

Custom Anodizing Color Samples

MachMaster provides in-house anodizing services with full control over quality, finish consistency, and color stability. Our color reference samples demonstrate the typical anodized finishes available for aluminum components.

We support both standard industry colors and customized finishes based on RAL or Pantone codes, enabling alignment with your product or brand requirements.

These samples are created under production-grade conditions to reflect the actual finish achievable on final parts.

• Compatible with AL6061, AL5052, and other engineering-grade alloys

• Surface options: matte, satin, semi-gloss

• Batch-to-batch color consistency is guaranteed under strict QA control

Sample color cards are available upon request for engineering review or procurement reference.

Why MachMaster Is the Right Choice

We combine engineering precision with production flexibility—offering tight tolerances, diverse materials, and fast lead times to meet your manufacturing needs. Whether you require prototypes or complex end-use parts, MachMaster delivers consistent quality and performance.

Tight Tolerance Accuracy

Parts machined to ±0.01 mm for functional fit, surface finish, and critical dimensions.

Low-Volume Friendly

From one-off prototypes to short runs—no MOQ, fast response, flexible output.

Precision for Complex Parts

Equipped with 60+ CNC machines for multi-surface and complex contour machining.

Material Versatility

Supports aluminum, stainless steel, brass, POM, PC, and other engineering plastics.

ISO 9001 Certified Workflow

Triple-stage inspection ensures every part meets your spec before shipment.

Rapid Lead Times

Prototypes delivered in as fast as 1 day, with full tracking and schedule control.

Speed Meets Precision at MachMaster

See our team, process, and precision in action at Xiamen MachMaster Co., Ltd—where every part is backed by expertise, systems, and measurable results.

Why Choose Anodizing?

Anodizing enhances both the performance and appearance of aluminum parts. From corrosion resistance to aesthetic versatility, it offers a durable, eco-friendly surface solution trusted across industries.

Corrosion Resistance

Protects aluminum surfaces from rust, moisture, and chemical exposure—ideal for harsh environments.

Surface Durability

Creates a harder, wear-resistant finish that prevents scratches and surface damage.

Aesthetic Flexibility

Supports custom colors and finishes for decorative or branded components.

Eco-Friendly Process

Non-toxic, long-lasting finish that won’t chip, peel, or flake—better for the environment.

FAQ About Anodizing

What Is Anodizing And How Does It Work?

Anodizing is an electrochemical process that converts the surface of metals—most commonly aluminum—into a durable, corrosion-resistant, and decorative oxide finish. The part is submerged in an acid electrolyte bath and an electric current is applied, forming a protective layer.

What Are The Benefits Of Anodizing Metal Parts?

Anodized finishes offer enhanced corrosion resistance, improved surface hardness, long-term durability, and a wide range of aesthetic color options. It also provides better adhesion for paints, dyes, and sealants.

What Materials Can Be Anodized?

Aluminum and its alloys are the most suitable and commonly anodized materials. Some magnesium and titanium alloys can also be anodized under specific conditions, but aluminum provides the most stable and economical results.

What Are The Typical Applications Of Anodized Parts?

Anodizing is widely used in industries such as aerospace, automotive, consumer electronics, architecture, and CNC machining—anywhere parts need to combine durability with appearance and color consistency.

How Thick Is The Anodized Layer, And Will It Affect Part Dimensions?

Anodizing thickness usually ranges from 5 to 25 microns. The layer partially penetrates the base material and builds up externally. While thin, this can affect high-precision components, so dimensional tolerances must account for the added layer.

Explore More of Our Resources

Anodizing Basics & Processes:

Anodizing Types & Variations:

- 6 Different Types of Anodizing & Their Key Benefits

- Anodizing Black Aluminum: A Quick Guide

- What is Hard Coat Anodized?

Alternative & Comparative Finishes:

- Alodine Coating: What You Need to Know

- Anodizing vs Electroplating: Key Differences Explained

- Anodizing vs Galvanizing: What’s the Difference

- Black Oxide Metal Finishing: What You Need to Know

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.

Tell Us What You Need

At MachMaster, our engineers review every request and respond with tailored solutions.

Your files are kept strictly confidential and will only be used for quoting and manufacturing purposes.

- info@machcncmaster.com

- +86 139 5006 6486