Sheet Metal Fabrication Services

China Sheet Metal Fabrication Supplier

MachMaster offers customized sheet metal fabrication services covering the full process—from design and material sourcing to cutting, forming, surface finishing, and assembly.

Our operations are backed by a skilled engineering team and advanced equipment, including CNC laser cutters, punching machines, and bending systems. These resources allow us to efficiently handle both simple and complex sheet metal projects with precision.

Every stage is tightly quality-controlled, from raw material selection to final inspection. As an ISO 9001:2015 certified manufacturer, we ensure every part we deliver meets both international standards and customer specifications.

Our Custom Sheet Metal Fabrication Services

We provide a full range of sheet metal fabrication processes—including laser cutting, stamping, bending, welding, and surface finishing—customized to meet the needs of different industries and application requirements.

Laser Cutting

It uses a high-power laser beam to cut materials. It offers fast speed and high precision.

Bending

It is a cold forming process that uses matched tools—an upper punch and a lower V-die—to plastically deform a blank, thereby achieving predetermined angles and shapes.

Welding

Welding is a process that uses heat, pressure, or both to create a permanent bond between two or more workpieces at the atomic level.

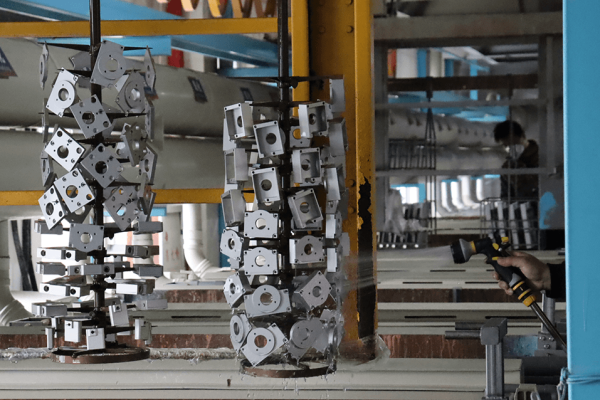

Surface Finishing

We offer surface finishing treatments such as powder coating, anodizing, electrolytic polishing, and electrophoretic finishing.

Manage Your Machining Needs with MachMaster

Manufacturing Materials

We offer a variety of sheet metal materials, including aluminum, brass, stainless steel, and copper. Each material has unique properties—such as strength, corrosion resistance, or conductivity—that make it suitable for specific applications across different industries.

Aluminum

Aluminum is a lightweight, silver-white metal known for its excellent machinability and strength-to-weight ratio. It is ideal for Bending due to its low density, corrosion resistance, and clean surface finish.

Stainless Steel

Stainless steel is a strong and durable alloy containing at least 10.5% chromium, offering excellent corrosion resistance. It’s widely used in high-strength applications across industrial, medical, and structural fields.

Brass

Brass is valued for its low friction, good machinability, and high electrical conductivity. Its golden appearance also makes it a popular choice for both decorative and functional components.

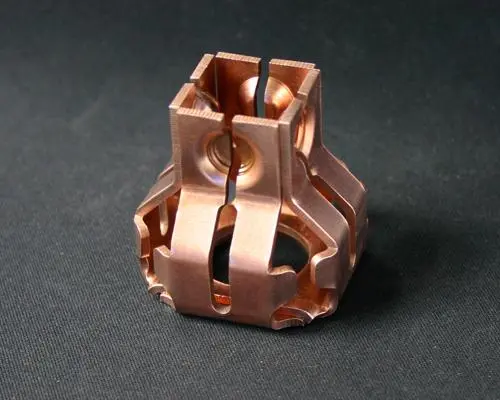

Copper

Copper offers outstanding electrical and thermal conductivity, along with excellent ductility and corrosion resistance. It is easy to machine and weld, making it suitable for electrical and thermal management applications.

Why MachMaster Is the Right Choice

We combine engineering precision with production flexibility—offering tight tolerances, diverse materials, and fast lead times to meet your manufacturing needs. Whether you require prototypes or complex end-use parts, MachMaster delivers consistent quality and performance.

Tight Tolerance Accuracy

Parts machined to ±0.01 mm for functional fit, surface finish, and critical dimensions.

Low-Volume Friendly

From one-off prototypes to short runs—no MOQ, fast response, flexible output.

Precision for Complex Parts

Equipped with 60+ CNC machines for multi-surface and complex contour machining.

Material Versatility

Supports aluminum, stainless steel, brass, POM, PC, and other engineering plastics.

ISO 9001 Certified Workflow

Triple-stage inspection ensures every part meets your spec before shipment.

Rapid Lead Times

Prototypes delivered in as fast as 1 day, with full tracking and schedule control.

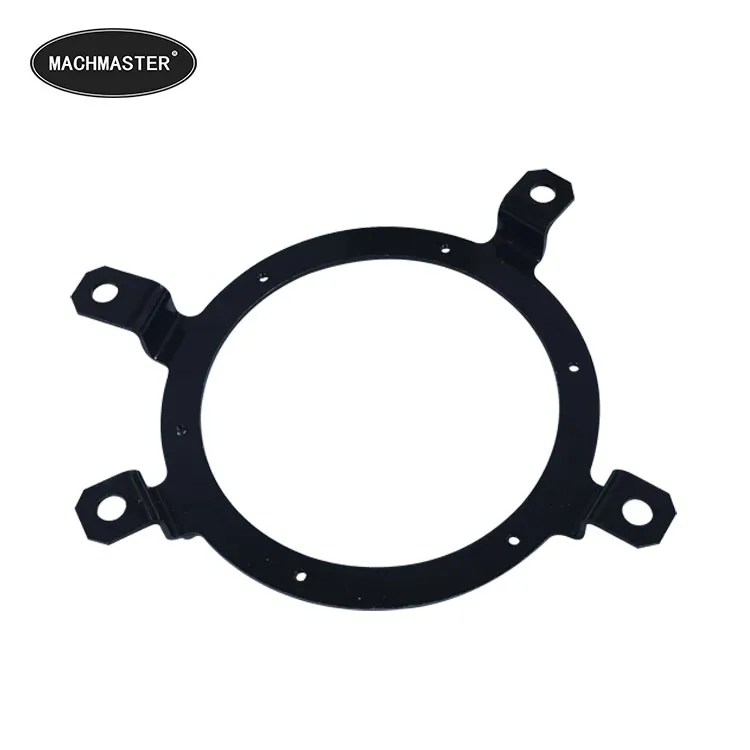

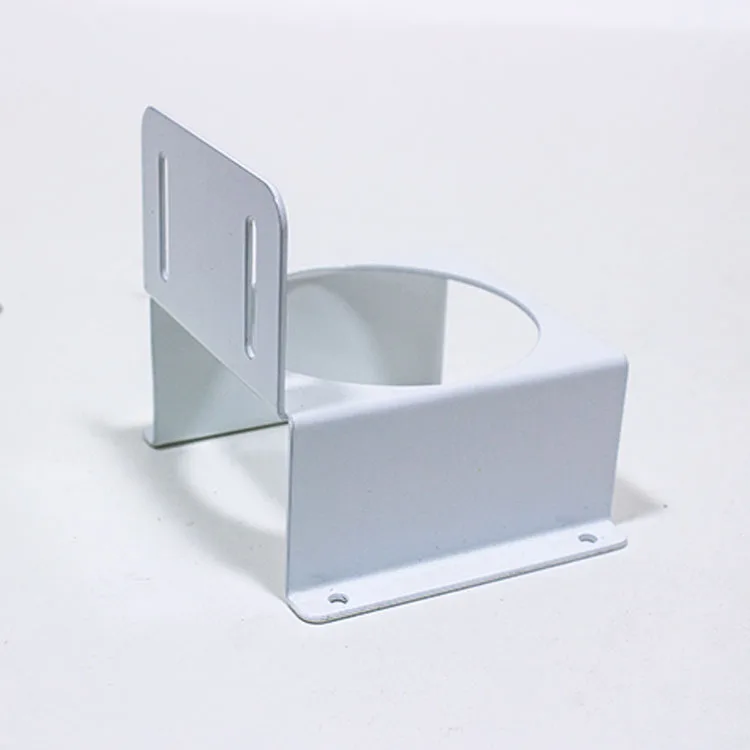

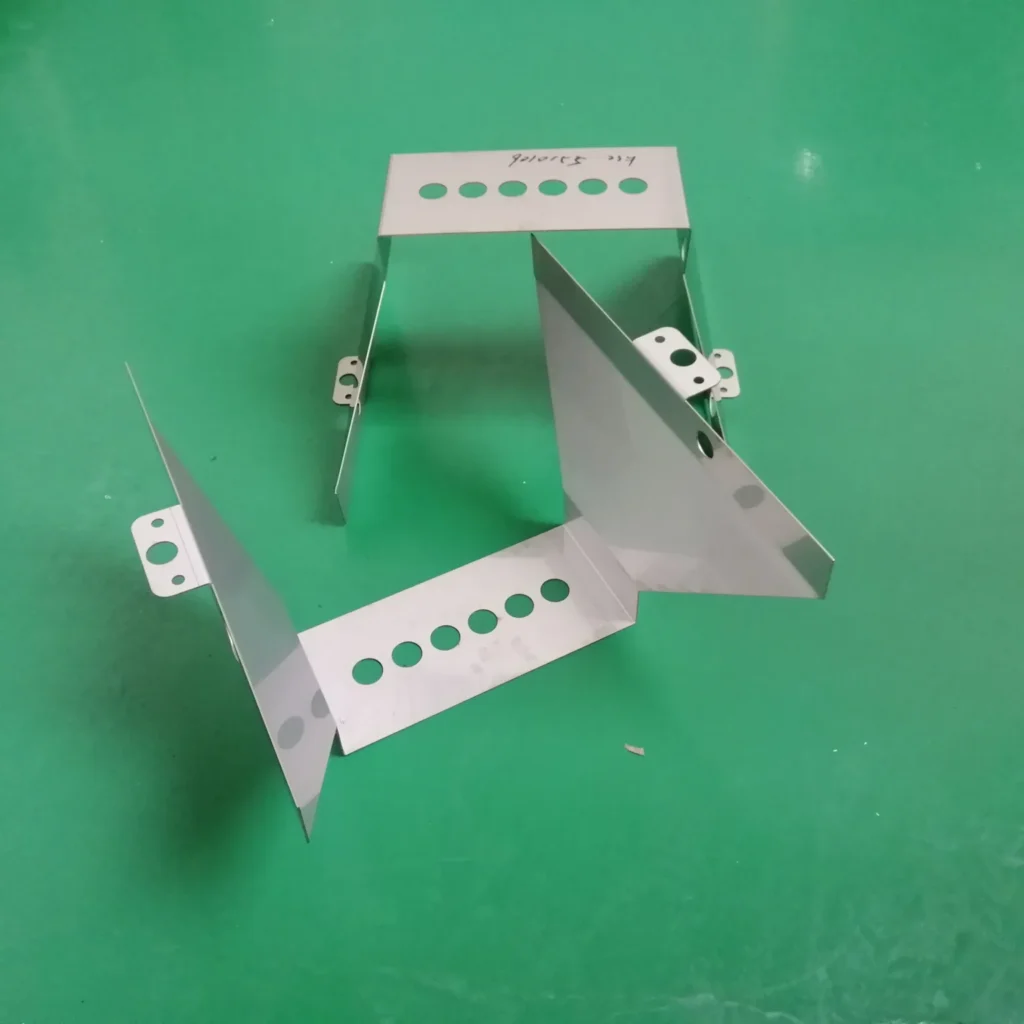

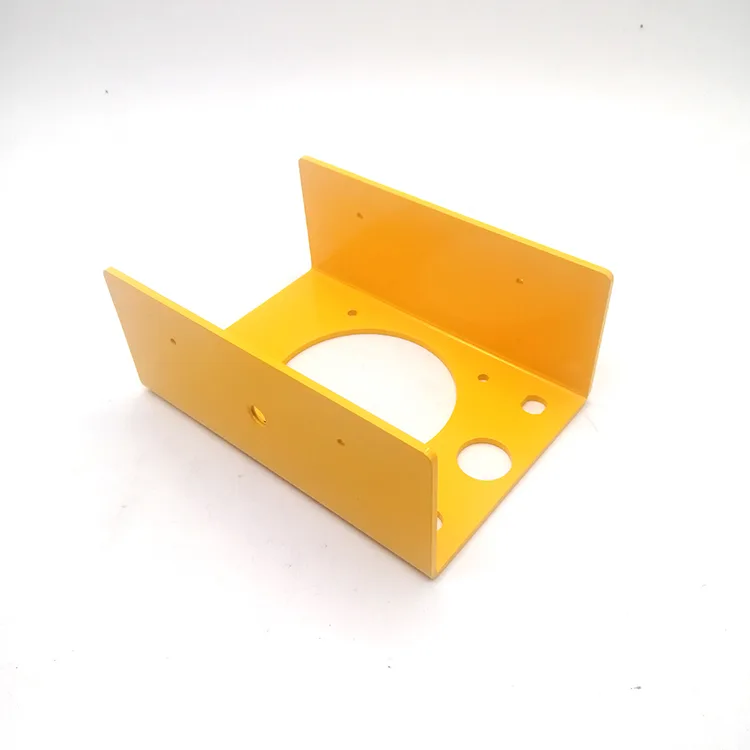

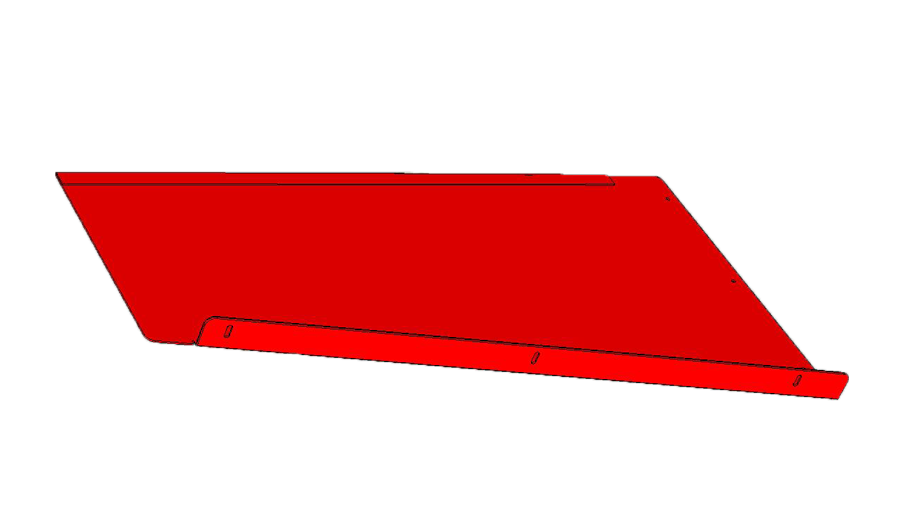

Real-World Sheet Metal Fabrication Samples

See examples of sheet metal fabrication parts we’ve produced for aerospace, medical, electronics, and other demanding industries.

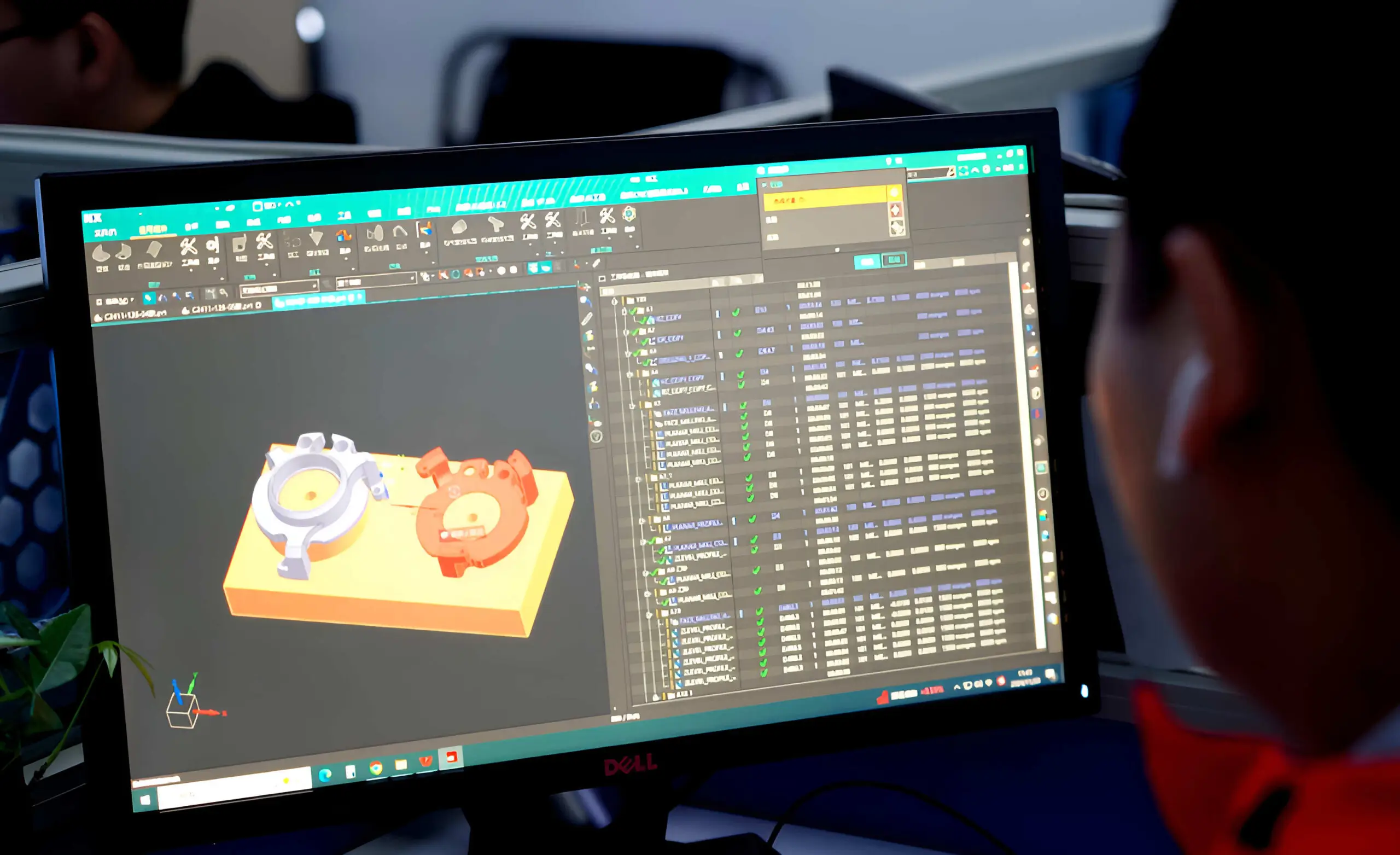

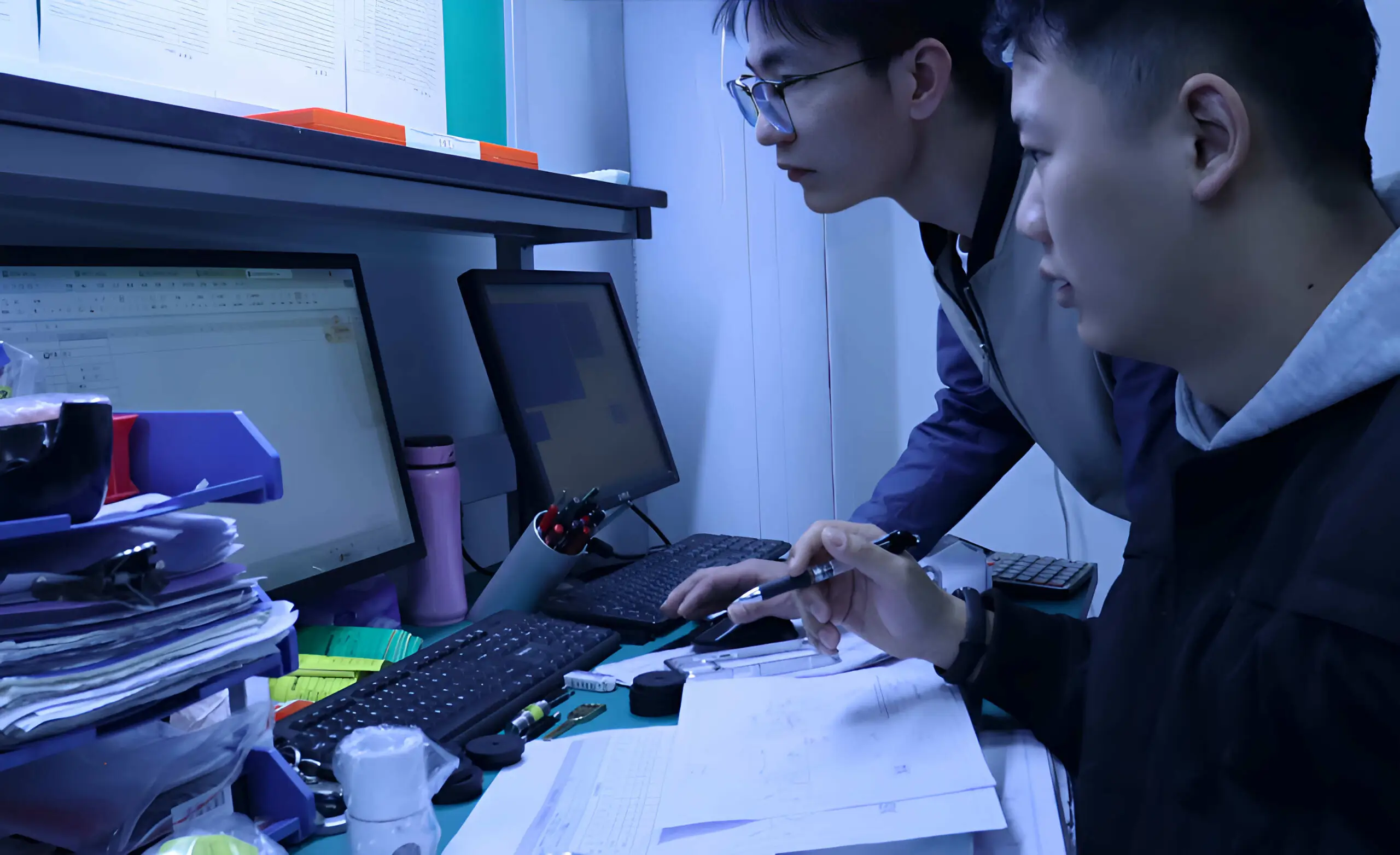

Speed Meets Precision at MachMaster

See our team, process, and precision in action at Xiamen MachMaster Co., Ltd—where every part is backed by expertise, systems, and measurable results.

Built by Experts, Backed by Process

At MachMaster, every project is supported by a dedicated team of experts across engineering, production, quality control, logistics, quoting, and customer support. Through integrated collaboration and precise process management, we ensure consistent quality, reliable delivery, and exceptional service at every stage of your project.

Project & Quotation Team

Manages files, RFQs, and lead time tracking with 24h quoting.

Engineering Team

Provides DFM analysis and technical solutions from design review to production readiness.

Production Team

Runs CNC, molding, casting, and finishing with precision and process control.

Quality Control Team

Handles inspection at every stage with full traceability and ISO standards.

Packaging & Logistics Team

Customizes packaging and ensures safe delivery with accurate scheduling.

Customer Support Team

Handles progress updates, feedback, and after-sales issues with fast response.

FAQ About Sheet Metal Fabrication

What Is Sheet Metal Fabrication?

Sheet metal fabrication is a cold-forming process that involves cutting, bending, welding, stamping, and surface treatment of thin metal sheets. A key feature is that the thickness of the material remains consistent throughout. It is widely used in electronics, automotive, telecommunications, and medical device industries.

What Is the Typical Process Flow for Sheet Metal Fabrication?

The full process includes:

Design – CAD drawing and process planning

Material Preparation – Metal sheet selection and cutting

Cutting – Using shears or laser machines

Bending – Forming angles with a press brake

Stamping – Punching holes, forming depressions or protrusions

Welding – Joining metal components

Surface Treatment – Polishing, powder coating, anodizing, etc.

Assembly – Final integration of parts into a complete product

What Are the Main Types of Sheet Metal Fabrication?

Shearing – Cuts metal sheets to specific sizes using mechanical force

Stamping – Uses dies to shape the metal through bending, stretching, or punching

Bending – Forms the sheet into angles along predetermined lines

What Is the Difference Between Sheet Metal Fabrication and Machining?

The key difference lies in the material form and how it is processed.

Machining starts with solid metal blocks and removes material to create a part.

Sheet metal fabrication begins with flat metal sheets and forms parts through bending and deformation.

This leads to differences in equipment, processes, and applications.

Explore More of Our Resources

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.

Tell Us What You Need

At MachMaster, our engineers review every request and respond with tailored solutions.

Your files are kept strictly confidential and will only be used for quoting and manufacturing purposes.

- info@machcncmaster.com

- +86 139 5006 6486