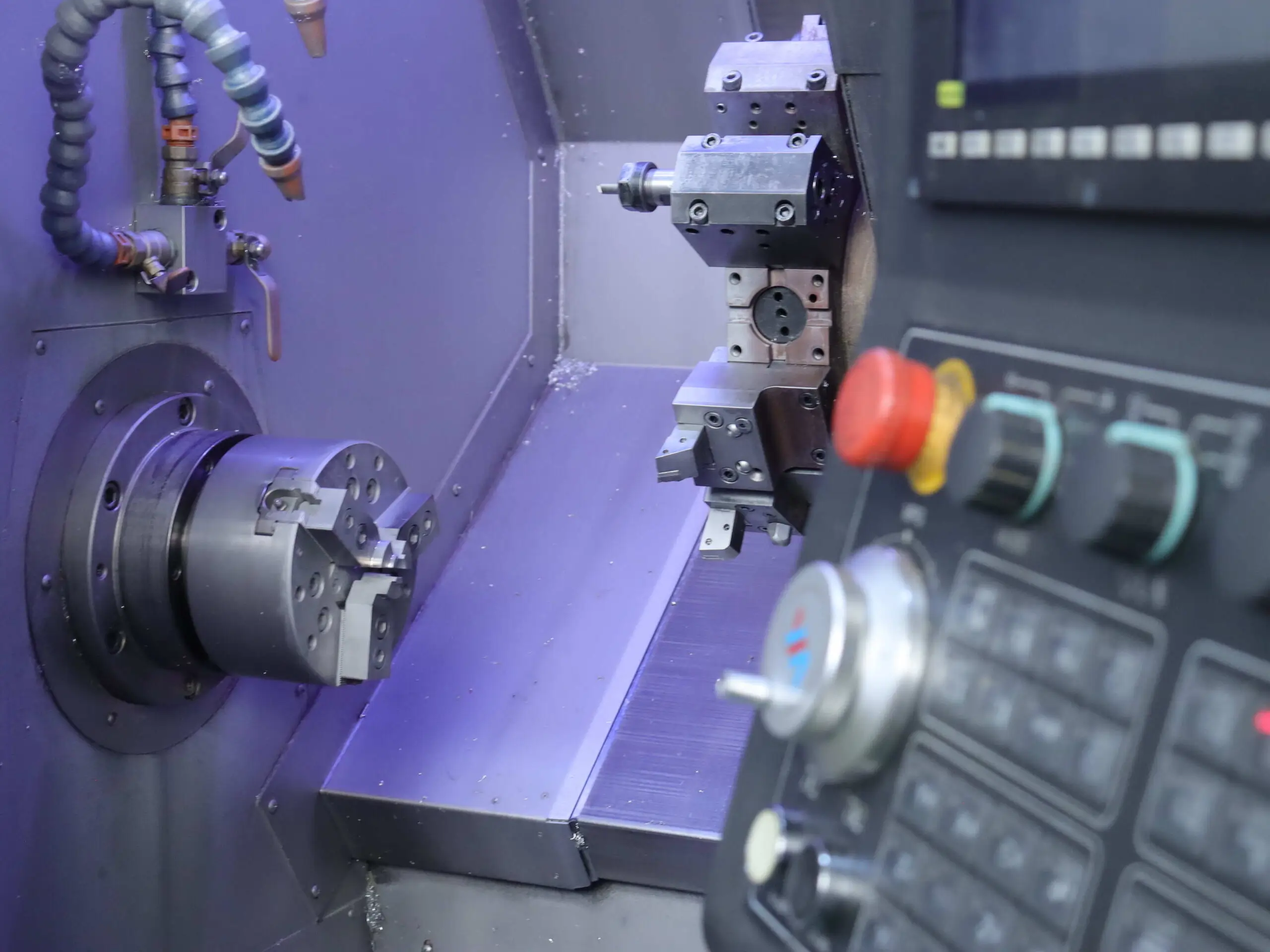

Quick Turn & Custom CNC Turning Services

Expert CNC Turning Services From China

Our CNC turning services deliver high-precision parts in as fast as 3 days, supporting both rapid prototyping and production needs with live tooling capabilities.

MachMaster factory specializes in CNC turning for both simple and complex components, delivering tight tolerances and consistent quality across a range of industries. Our advanced CNC lathes with live tooling enable precise machining of cylindrical shapes, radial holes, grooves, and flats—all in a single setup to enhance efficiency.

We process over 30 certified materials, including aluminum, stainless steel, brass, and engineering plastics, allowing us to meet diverse part requirements without sacrificing speed or accuracy.

All operations are managed under strict in-house quality control and ISO 9001:2015 certification, ensuring that every turned part meets your exact design, performance, and dimensional standards.

Manage Your Machining Needs with MachMaster

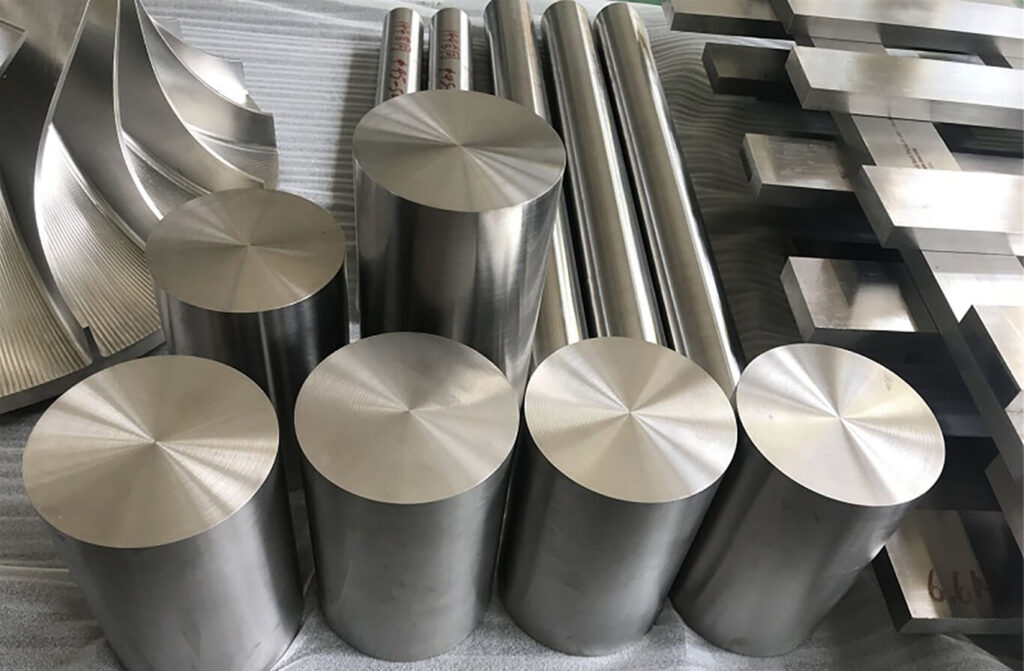

Materials for CNC Turning Parts

We support over 30 types of metals and plastics for CNC turning, offering flexibility from rapid prototyping to full-scale production. Get instant quotations, compare material costs, and choose the best fit for your design and performance needs.

Aluminum

Aluminum is a lightweight, silver-white metal known for its excellent machinability and strength-to-weight ratio. It is ideal for CNC turning milling due to its low density, corrosion resistance, and clean surface finish.

| Available Aluminum at Machmaster: | Aluminum 6061, 6061-T6, Aluminum 2024, Aluminum 5052, Aluminum 5083, Aluminum 6063, Aluminum 6082, Aluminum 7075, 7075-T6, Aluminum ADC12 (A380) |

Stainless Steel

Stainless steel is a strong and durable alloy containing at least 10.5% chromium, offering excellent corrosion resistance. It’s widely used in high-strength applications across industrial, medical, and structural fields.

| Available Stainless Steel at Machmaster: | Stainless Steel SUS201, SUS303, SUS 304, SUS316, SUS316L, SUS42, SUS430, SUS431, SUS440C, SUS630/17-4PH, AISI 304 |

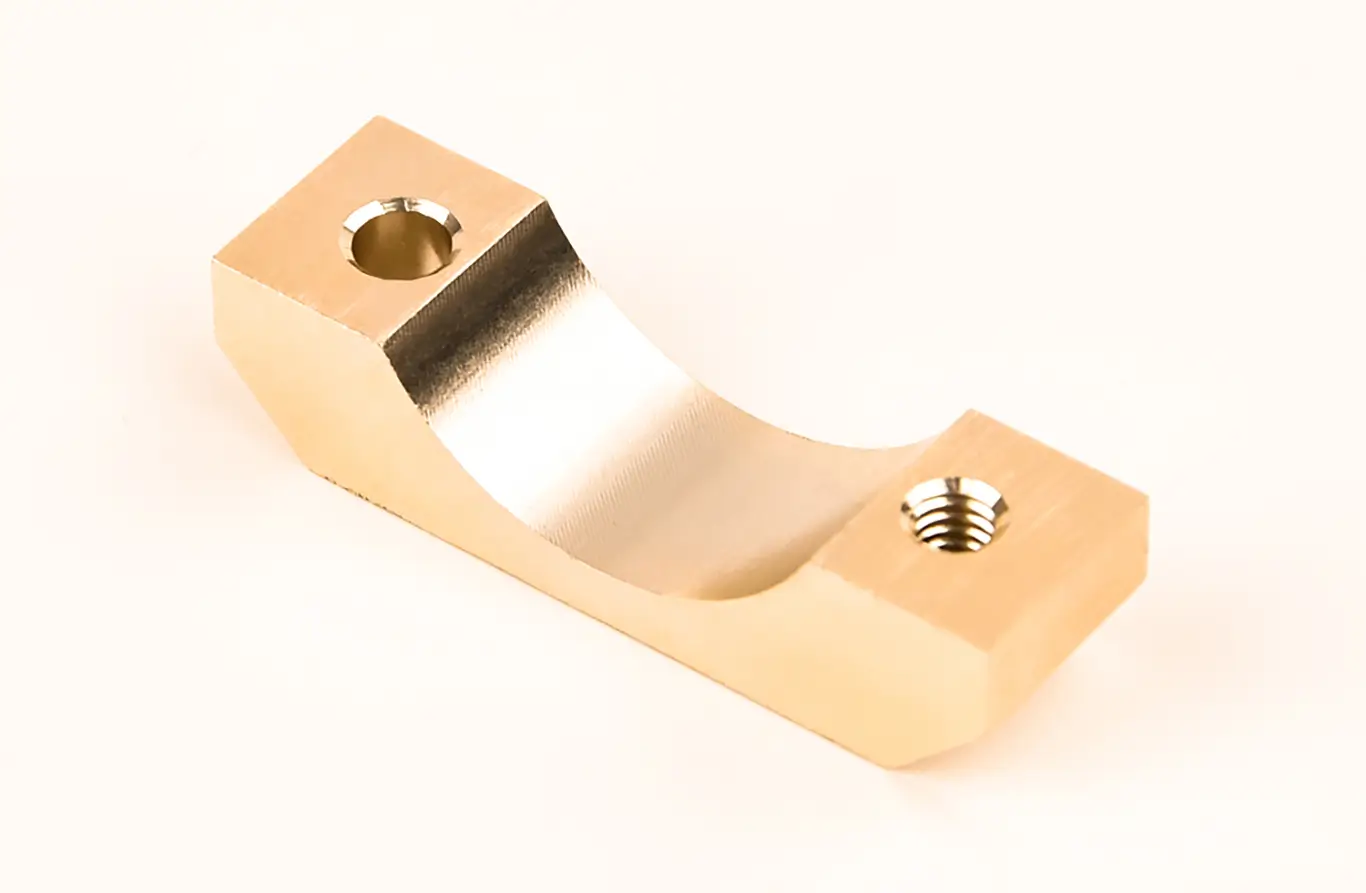

Brass

Brass is valued for its low friction, good machinability, and high electrical conductivity. Its golden appearance also makes it a popular choice for both decorative and functional components.

| Available Brass at Machmaster: | Brass C27400, C28000, C36000 |

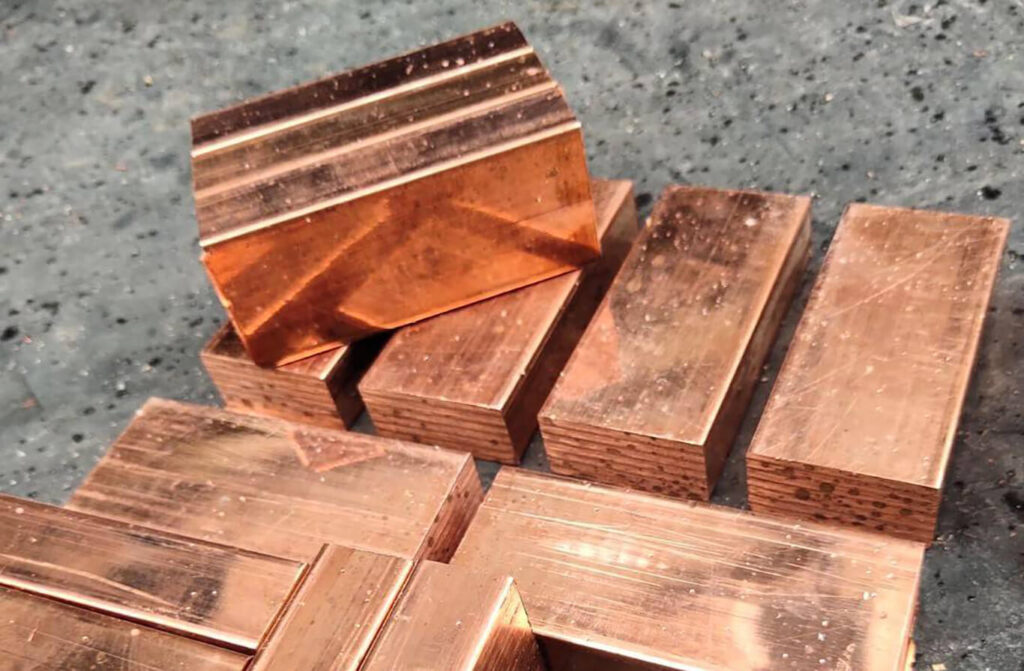

Copper

Copper offers outstanding electrical and thermal conductivity, along with excellent ductility and corrosion resistance. It is easy to machine and weld, making it suitable for electrical and thermal management applications.

| Available Copper at Machmaster: | Copper C101(T2), C103(T1), C103(TU2), C110(TU0), Beryllium Copper |

Titanium

Titanium is a lightweight yet high-strength metal with excellent corrosion resistance. Commonly used in aerospace, medical, and high-performance industries, it provides a superior strength-to-weight ratio for demanding applications.

| Available Titanium at Machmaster:: | Titanium Alloy TA1, Alloy TA2, Alloy TC4/Ti-6Al 4V |

Plastics

Plastics are a versatile and cost-effective option for CNC machining. They offer faster processing speeds and come in a wide range of types, suitable for both structural and functional components in prototyping and production.

| POM | PEEK | HDPE | PET |

| Nylon | PTFE | PVC | PP |

| ABS | PC | PMMA |

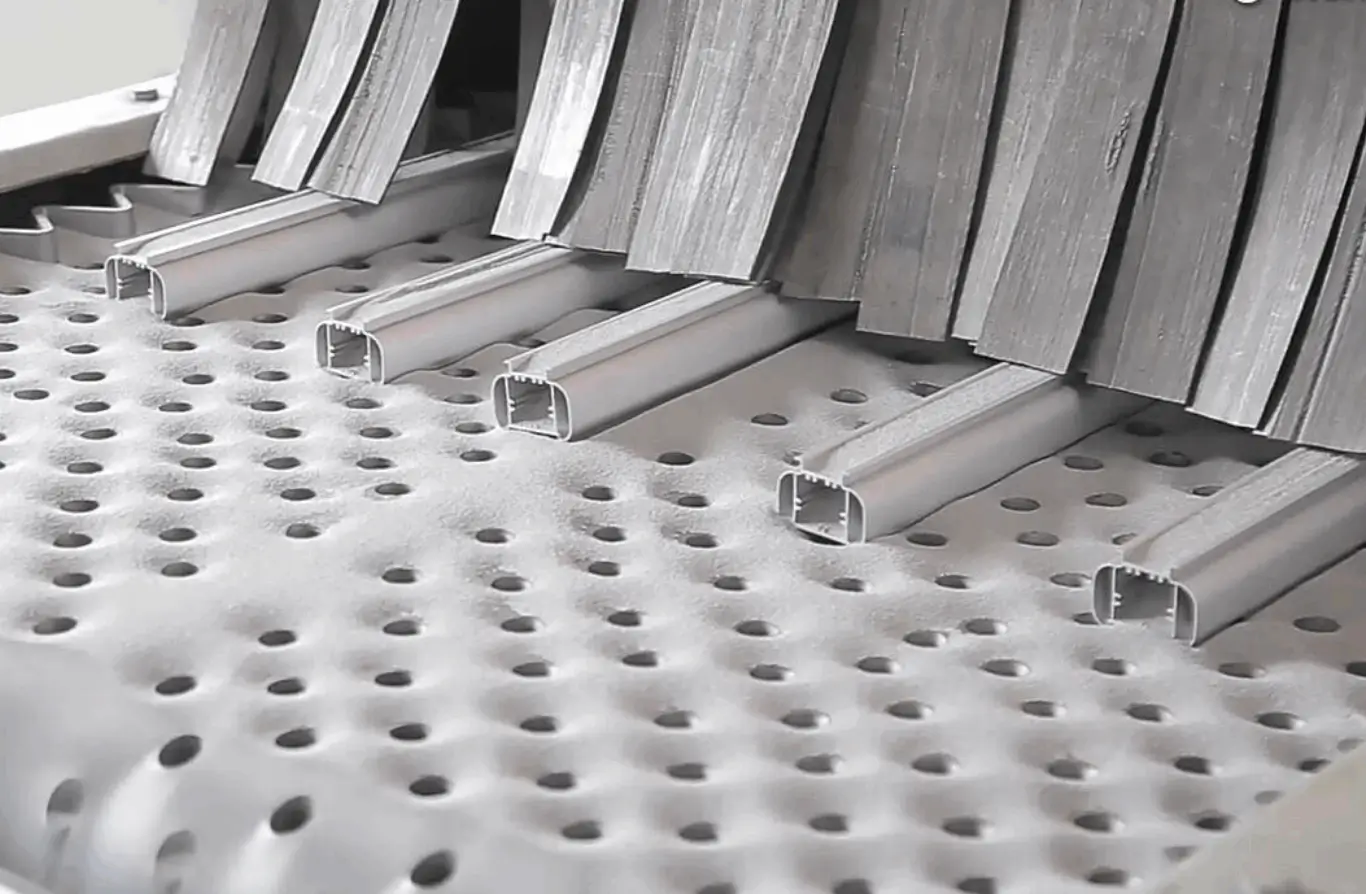

Surface Finishes for CNC Turned Parts

CNC-turned parts often require post-processing to improve surface smoothness, corrosion resistance, or appearance. MachMaster offers a variety of finishing options to enhance both function and aesthetics of your turned components.

As machined

The part is left as-is from CNC machining, offering a cost-effective solution with visible tool marks and a standard roughness of 3.2 μm (126 μin), plus deburring for safe handling.

Anodizing

Anodizing enhances corrosion and wear resistance by forming a protective oxide layer on aluminum or titanium surfaces. It also allows for decorative coloring and improves overall part durability.

Alodine

Applied primarily to aluminum, Alodine coating creates a corrosion-resistant and paint-ready surface, significantly improving both protection and finish durability.

Bead Blasting

Bead blasting produces a uniform matte finish by removing surface imperfections. Commonly used to improve appearance before anodizing, plating, or coating.

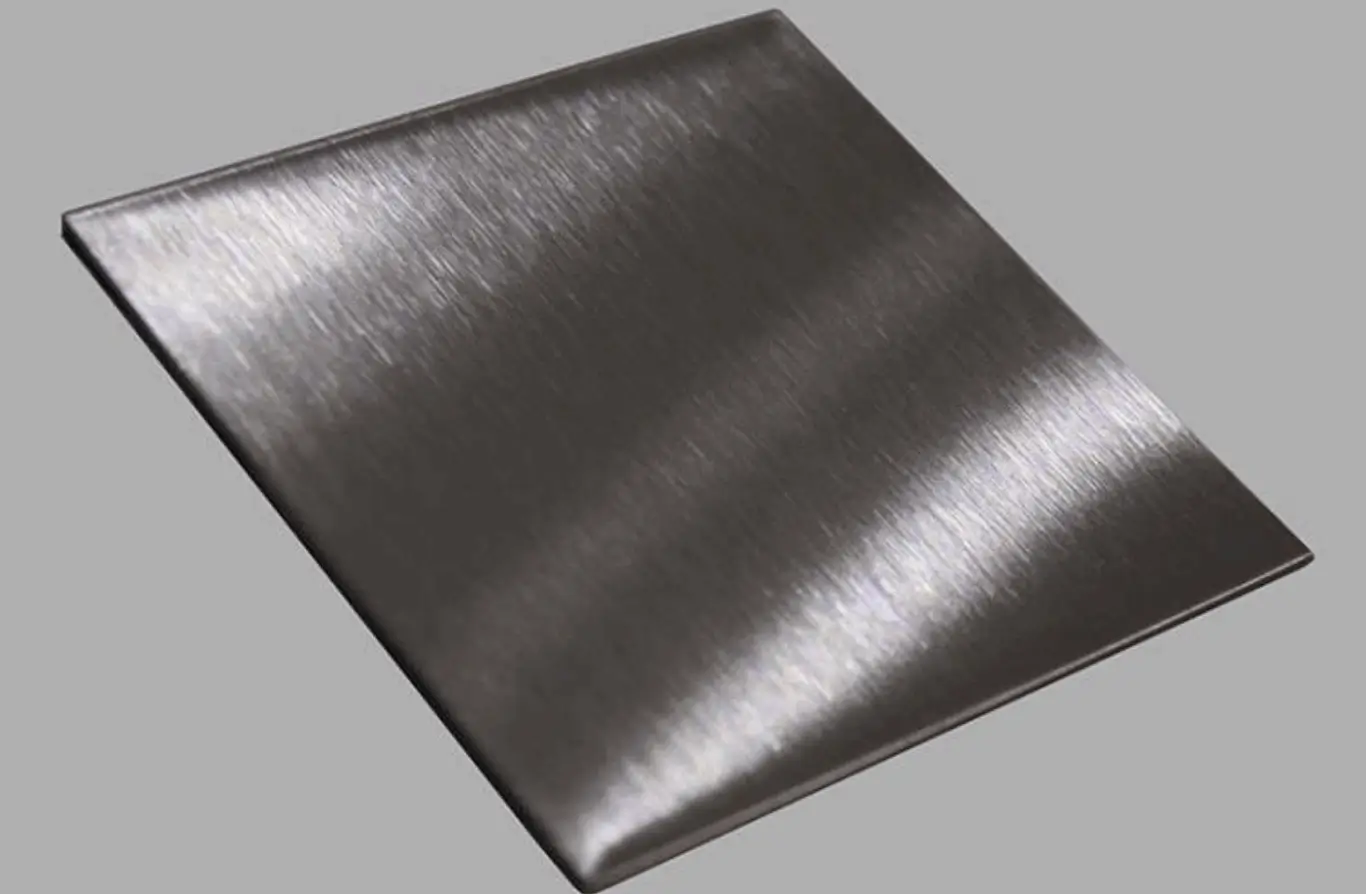

Brushing

Brushing applies a fine, directional texture using abrasive belts or pads. Often used for decorative metal finishes or to visually mask minor surface defects.

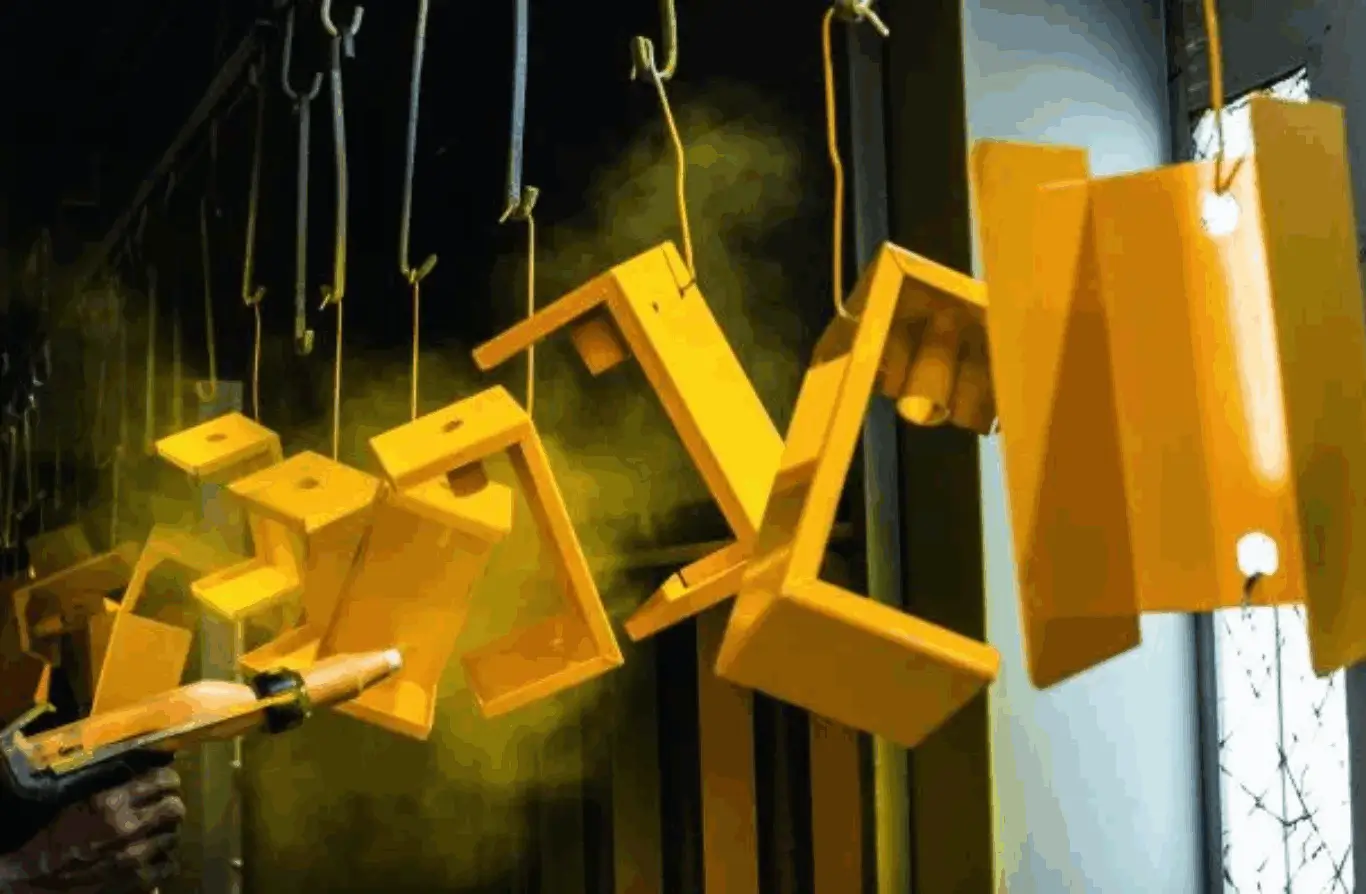

Powder Coating

This dry finishing process applies powder to metal parts, then cures it into a tough, uniform coating. It offers excellent durability and is available in many colors and textures.

Electroplating

Electroplating uses electric current to deposit a metal layer onto a part, enhancing hardness, conductivity, and appearance with finishes like chrome or nickel.

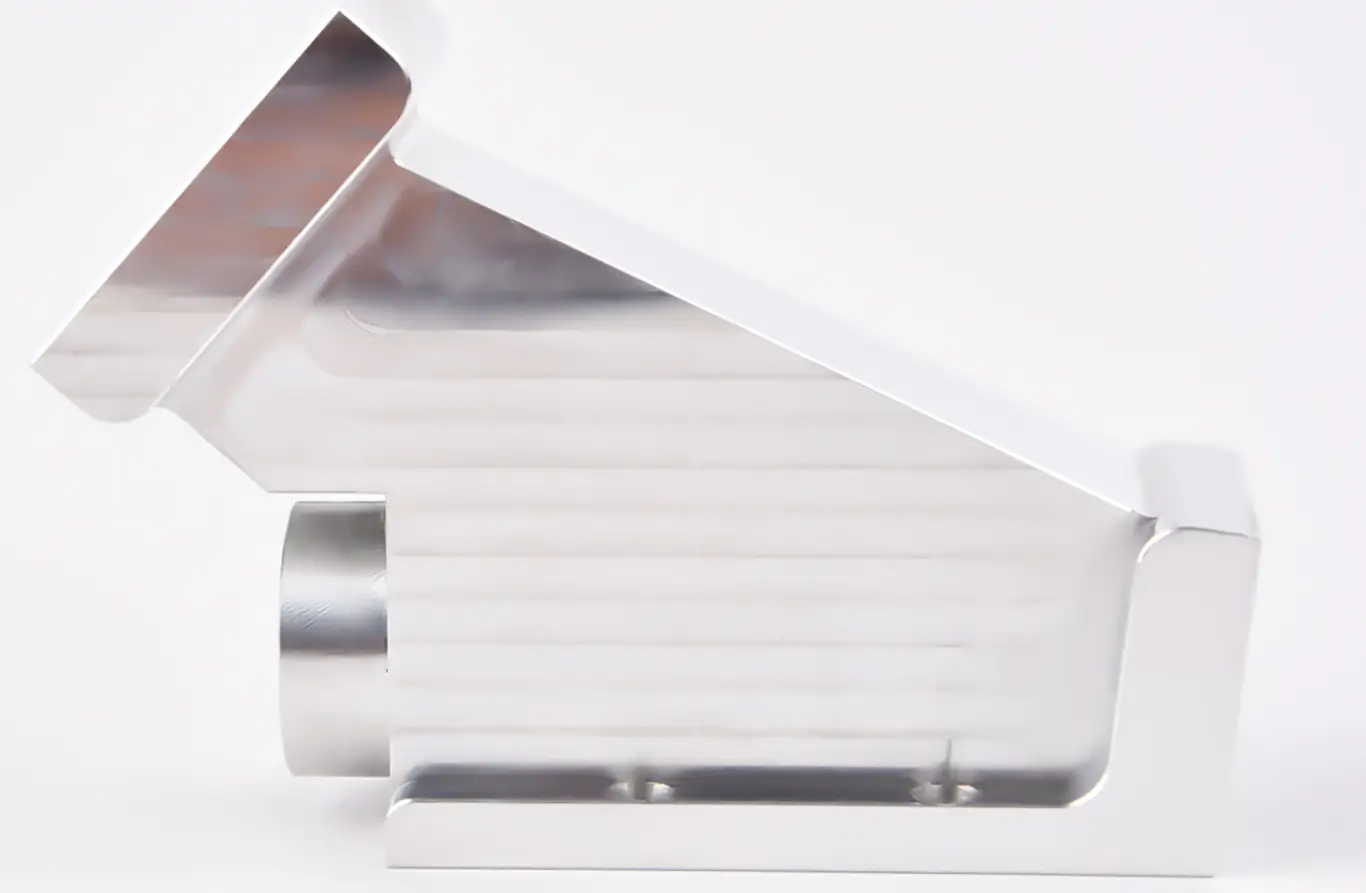

Polishing

Polishing removes surface flaws and creates a reflective, smooth finish. It’s used to improve aesthetics, reduce friction, and prepare parts for secondary coatings.

CNC Turning Highlights

Tight Tolerance Accuracy

Parts machined to ±0.01 mm for functional fit, surface finish, and critical dimensions.

Low-Volume Friendly

From one-off prototypes to short runs—no MOQ, fast response, flexible output.

Precision for Complex Parts

Equipped with 60+ CNC machines for multi-surface and complex contour machining.

Material Versatility

Supports aluminum, stainless steel, brass, POM, PC, and other engineering plastics.

ISO 9001 Certified Workflow

Triple-stage inspection ensures every part meets your spec before shipment.

Rapid Lead Times

Prototypes delivered in as fast as 1 day, with full tracking and schedule control.

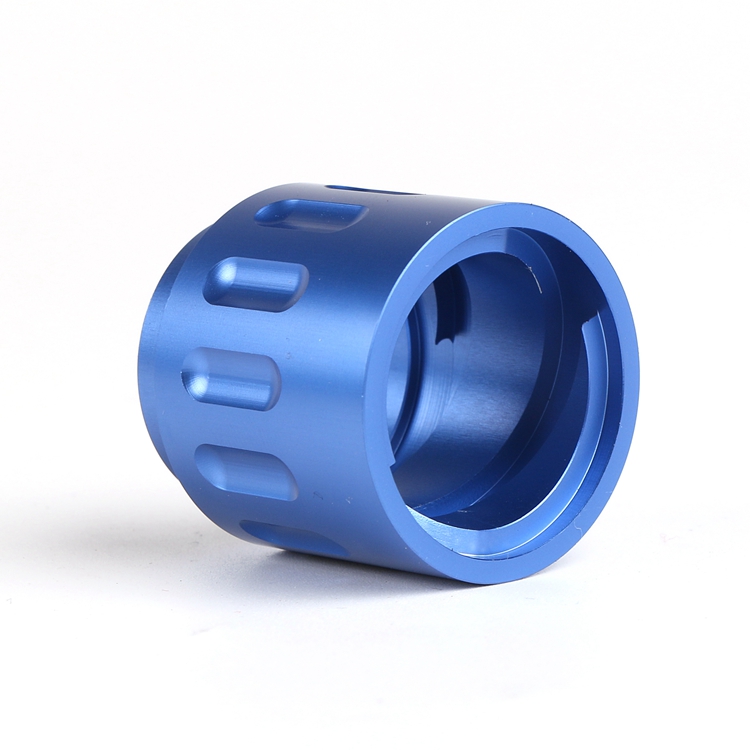

Real-World CNC Turning Samples

See examples of CNC turned parts we’ve produced for aerospace, medical, electronics, and other demanding industries.

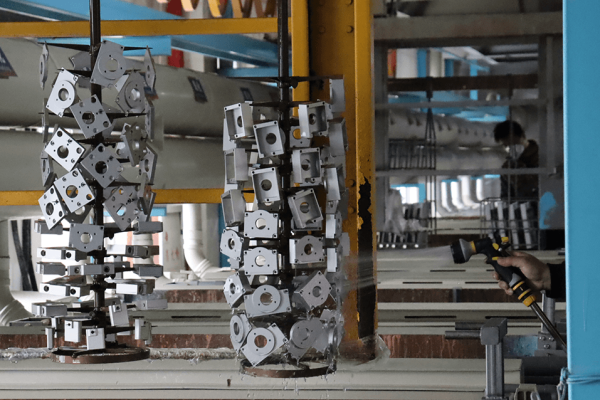

Speed Meets Precision at MachMaster

See our team, process, and precision in action at Xiamen MachMaster Co., Ltd—where every part is backed by expertise, systems, and measurable results.

CNC Turning Tolerances

MachMaster delivers ±0.005″ precision on CNC-turned parts, meeting ISO 2768-m/c standards for metals and plastics.

| Type | CNC Turning | |

|---|---|---|

| Maximum Part Size |

200×500 mm

7.9×19.7 in. |

|

| Minimum Part Size |

1×1 mm

0.079×0.079 in. |

|

| Minimum Feature Size |

Φ 0.50 mm

Φ 0.00197 in. |

|

| Standard Tolerances |

Metals: ISO 2768-m

Plastics: ISO 2768-c |

|

| Linear Dimension |

+/- 0.01 mm

+/- 0.001 in. |

|

|

Hole Diameters

(Not Reamed) |

+/- 0.025 mm

+/- 0.001 in. |

|

| Shaft Diameters |

+/- 0.025 mm

+/- 0.001 in. |

|

| Threads and Tapped Holes |

Diameter: Φ 1.5-5 mm, depth: 3×diameter

Diameter: Φ 5 mm or more, depth: 4-6×diameter |

|

| Text | MachMaster can use laser marking to create standard text for CNC turned parts. | |

| Edge Condition | Sharp corners will be removed in the form of a chamfer or radius. The size of the chamfer, or resulting radii, must be indicated on the drawing. | |

Advantages of CNC Turning

CNC turning offers speed, precision, and material flexibility, making it ideal for producing round or cylindrical parts across industries like aerospace, medical, and automotive.

Precision & Consistency

CNC turning ensures tight tolerances and stable repeatability, making it ideal for both functional prototypes and high-requirement production parts.

Smooth Surface Finishes

The turning process delivers clean and uniform surface finishes with excellent dimensional control, reducing or even eliminating the need for additional post-processing.

Fast Turnaround & Scalability

With fast setup times and high machining efficiency, CNC turning supports short lead times and seamless scaling from small batches to large-volume production.

Complex Features with Minimal Waste

Advanced tooling supports the creation of threads, grooves, tapers, and other detailed geometries, all with high material utilization and minimal scrap.

Precision CNC Turning: What You Need to Know

What Is CNC Turning?

CNC turning is a subtractive manufacturing process performed on a lathe. A metal or plastic rod is clamped into a rotating chuck, while a cutting tool precisely removes material to form cylindrical parts. This process is ideal for producing shafts, bushings, and other rotational components with tight tolerances.

How Is CNC Turning Cost Calculated?

The cost of CNC turning typically includes raw material, tooling setup, machining time, surface finishing, and packaging. A profit margin is applied to the total. Additional factors like part complexity, tolerance, and volume can also influence pricing.

How Much Does CNC Machining Cost in China?

In China, CNC machining rates vary by shop size and capability. Basic plastic milling may start at $5–10 per hour, while professional 3-axis to 5-axis machining typically ranges from $10–30 per hour. This is significantly more cost-effective than Europe or North America, where similar services can cost $30–60 per hour.

Explore More of Our Resources

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.

Tell Us What You Need

At MachMaster, our engineers review every request and respond with tailored solutions.

Your files are kept strictly confidential and will only be used for quoting and manufacturing purposes.

- info@machcncmaster.com

- +86 139 5006 6486